Impact Driver/Wrench 18V

Owners Manual

- 08 -

English |

17

Bosch Power Tools

1 609 92A 2CU | (2.11.16)

The lithium ion battery is protected against deep discharging

by the “Electronic Cell Protection (ECP)”. When the battery is

empty, the machine is switched off by means of a protective

circuit: The inserted tool no longer rotates.

Do not continue to press the On/Off switch after the

machine has been automatically switched off.

The bat-

tery can be damaged.

Observe the notes for disposal.

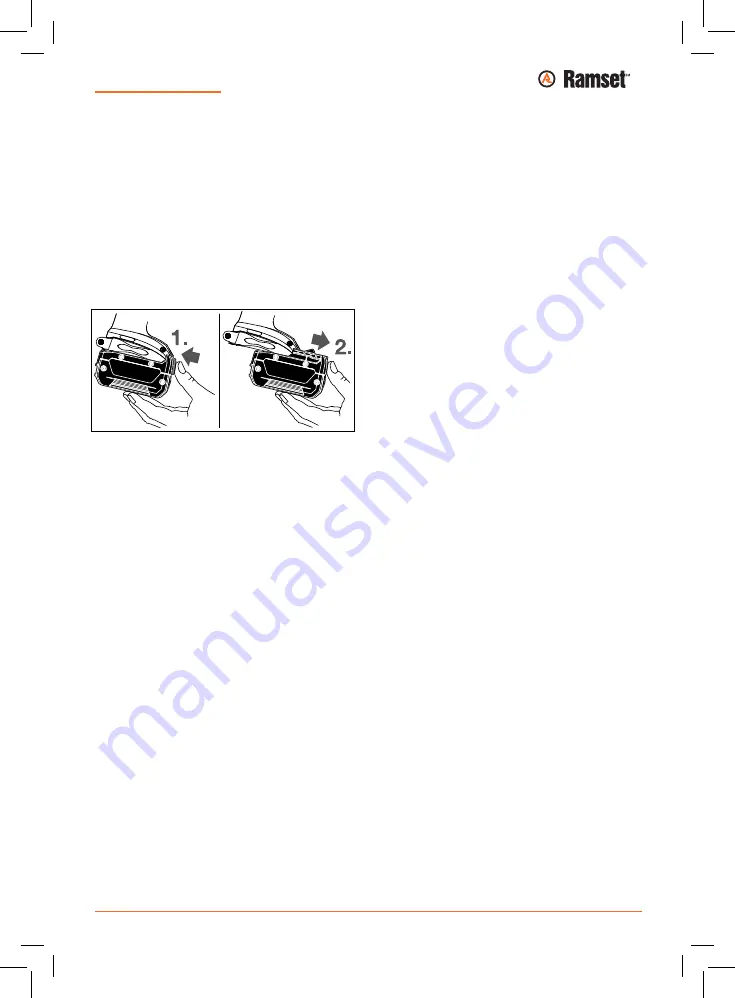

Removing the battery

The battery

4

is equipped with two locking levels that should

prevent the battery from falling out when pushing the battery

unlocking button

5

unintentionally. As long as the battery is

inserted in the power tool, it is held in position by means of a

spring.

To remove the battery

4

, press the unlocking button

5

and

pull out the battery toward the front.

Do not exert any force.

Changing the Tool

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

Regularly clean the power tool’s air vents.

The motor’s

fan will draw the dust inside the housing and excessive ac-

cumulation of powdered metal may cause electrical haz-

ards.

Inserting

Pull the locking sleeve

2

forward, push the insert tool to the

stop into the tool holder

1

and release the locking sleeve

2

to

lock the insert tool.

Screwdriver bits

16

can be inserted using a universal bit hold-

er with ball lock

15

.

Removing

Pull the locking sleeve

2

forward and remove the insert tool.

When working with an application tool, pay attention

that the application tool is connected securely on the

tool holder.

When the application tool is not securely con-

nected with the tool holder, it can come off during applica-

tion.

Slide the application tool

17

onto the square drive of the tool

holder

1

.

However based on the system, if the application tool

17

ap-

pears wobbly after connecting securely on the tool holder

1

;

this has no influence on the function/safety.

Some application tools (e.

g. double bits) cannot be safely se-

cured in the tool holder.

Operation

Method of Operation

The tool holder

1

with the tool is driven by an electric motor

via a gear and impact mechanism.

The working procedure is divided into two phases:

Screwing in

and

tightening

(impact mechanism in action).

The impact mechanism is activated as soon as the screwed

connection runs tight and thus load is put on the motor. In this

instance, the impact mechanism converts the power of the

motor to steady rotary impacts. When loosening screws or

nuts, the process is reversed.

Starting Operation

Inserting the battery

Use only original

Ramset

lithium ion batteries with the

voltage listed on the nameplate of your power tool.

Us-

ing other batteries can lead to injuries and pose a fire haz-

ard.

Set the rotational direction switch

9

to the centre position to

protect the power tool against accidental starting.

Insert the charged battery

4

from the front into the base of the

power tool until the battery is securely locked.

Reversing the rotational direction (see figure D)

The rotational direction switch

9

is used to reverse the rota-

tional direction of the machine. However, this is not possible

with the On/Off switch

10

actuated.

Right rotation:

For driving in screws and tightening nuts,

press the rotational direction switch

9

through to the left

stop.

Left Rotation:

For loosening and unscrewing screws and

nuts, press the rotational direction switch

9

through to the

right stop.

Switching On and Off

To

start

the machine, press the On/Off switch

10

and keep it

pressed.

To

switch off

the machine, release the On/Off switch

10

.

To save energy, only switch the power tool on when using it.

Adjusting the Speed

The speed of the switched on power tool can be variably ad-

justed, depending on how far the On/Off switch

10

is

pressed.

Light pressure on the On/Off switch

10

results in a low rota-

tional speed. Further pressure on the switch results in an in-

crease in speed.

OBJ_BUCH-2047-002.book Page 17 Wednesday, November 2, 2016 3:55 PM

18

| English

1 609 92A 2CU | (2.11.16)

Bosch Power Tools

Preselecting the Speed/Impact Frequency

With the button

6

you can preselect the required speed/im-

pact rate in three stages. Press the button

6

repeatedly until

the desired setting appears in the speed indicator

7

. The se-

lected setting will be saved.

The required speed/impact frequency depends on the mate-

rial and the working conditions, and can be determined

through practical testing.

Switching the “PowerLight” On/Off

To switch the “PowerLight”

11

on

, press button

8

. To switch

the “PowerLight”

11

off

, press button

8

again.

Working Advice

Apply the power tool to the screw/nut only when it is

switched off.

Rotating tool inserts can slip off.

The torque depends on the impact duration. The maximum

achieved torque results from the sum of all individual torques

achieved through impact. The maximum torque is achieved

after an impact duration of 6–10 seconds. After this dura-

tion, the tightening torque is increased only minimally.

The impact duration is to be determined for each required

tightening torque. The actually achieved tightening torque is

always to be checked with a torque wrench.

Screw Applications with Hard, Spring-loaded or Soft Seat

When in a test, the achieved torques in an impact series are

measured and transferred into a diagram, resulting in the

curve of a torque characteristic. The height of the curve corre-

sponds with the maximum reachable torque, and the steep-

ness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is given for metal-to-metal screw applications

with the use of washers. After a relatively short impact du-

ration, the maximum torque is reached (steep characteris-

tic curve). Unnecessary long impact duration only causes

damage to the machine.

– A

spring-loaded seat

is given for metal-to-metal screw ap-

plications, however with the use of spring washers, disc

springs, studs or screws/nuts with conical seat as well as

when using extensions.

– A

soft seat

is given for screw applications, e. g., metal on

wood or when using lead washers or fibre washers as back-

ing.

For a spring-loaded seat as well as for a soft seat, the maxi-

mum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

Reference Values for Maximum Screw/Bolt Tightening Torques

Calculated from the tensional cross-section; utilization of the yield point 90 % (with friction coefficient μ

total

= 0.12). As a control

measure, always check the tightening torque with a torque wrench.

Tips

Before screwing larger, longer screws into hard materials, it is

advisable to predrill a pilot hole with the core diameter of the

thread to approx.

2

/

3

of the screw length.

Note:

Pay attention that no metal particles enter the power

tool.

Belt Clip

With the belt clip

3

, the machine can be hung onto a belt. The

user has both hands free and the machine is always at hand.

Recommendations for Optimal Handling of the Battery

Protect the battery against moisture and water.

Store the battery only within a temperature range between

0 °C and 50 °C. As an example, do not leave the battery in the

car in summer.

Occasionally clean the venting slots of the battery using a soft,

clean and dry brush.

A significantly reduced working period after charging indi-

cates that the battery is used and must be replaced.

Observe the notes for disposal.

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

Property Classes accord-

ing to DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M 6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M 8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M 10

13

17.5

22

23

26

29

35

39

47

65

78

M 12

22.6

30

37.6

40

45

50

60

67

80

113

135

M 14

36

48

60

65

72

79

95

107

130

180

215

M 16

55

73

92

98

110

122

147

165

196

275

330

OBJ_BUCH-2047-002.book Page 18 Wednesday, November 2, 2016 3:55 PM