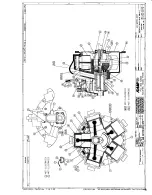

STEP 11

Secure bearing nut (14) by bending a lock washer (13) tab into one of four bearing nut slots. If no tab

aligns with a slot, the nut may be tightened until one of the slots aligns with a lock washer tab.

STEP 12

Assemble a washer (16), spring (17), a second washer (16), and a retaining ring (15) in the middle

grooves of input shaft (2). Install a second retaining ring (15) in groove near small end of input shaft (2).

STEP 13

Assemble the splined end of the input shaft (2) down into spindle (3).

STEP 14

Assemble the secondary carrier assembly (19) to spindle (3) at splines.

STEP 15

Clean mating surfaces and apply a bead of silicone sealant to face of hub (9) that mates with ring gear

(18). See instructions on sealant package. Assemble ring gear (18) to hub (9) being careful to align bolt

holes.

STEP 16

Assemble the primary carrier assembly (20) into the ring gear (18). It will be necessary to rotate carrier

to align secondary sun gear {part of primary carrier assembly (20)} with planet gear teeth in secondary

carrier assembly (19). Assemble primary sun gear (21) over input shaft (2). Rotate primary sun gear

(21) to align input shaft (2) to gear splines and gear teeth in primary carrier assembly (20).

STEP 17

Lubricate “O” ring (24) and assemble in groove inside cover hole, push disengage plunger (23) into

cover (25) with pointed end facing inside of unit.

STEP 18

Assemble the thrust washer (22) with tangs engaged with cover (25).

NOTE:

A small amount of grease

applied to the back side of thrust washer (22) will hold washer in place. Apply a bead of silicone sealant

to end of face of ring gear (18). Assemble cover (25) aligning holes of cover and ring gear. Assemble

the twentyfour 3/8-16 x 6-1/2 inch grade 8 bolts (26) and flat washers (27). Torque bolts to 45 - 50 lb.-ft.

(61 - 67 Nm).

STEP 19

Assemble the disengage cover (30) with dimpled center protruding out if wheel is to be used to drive

the vehicle. Assemble and torque the two 5/16-18 x 1/2 inch bolts (31). Torque bolts to 10 - 20 lb.-ft. (13

- 27 Nm).

STEP 20

Invert the Wheel Drive assembly and assemble the coupling (1) with counter bore out to the input shaft

(2)

STEP 21

After motor is assembled to drive or drive is sealed at spindle, fill with lubricant to proper level and

replace all plugs.

Note: When installing a hydraulic motor to the Wheel Drive it is necessary to place an “O” ring or

gasket between the motor and the planetary drive. “O” ring sizes: SAE A 2-042, SAE B 2-155, SAE C

2-159.

Содержание K5UR120ML-AM1G Series

Страница 1: ...MODEL K5UR120ML XX AM1G UTILITY AND MANLIFTER AIR WINCH ...

Страница 2: ......

Страница 3: ......

Страница 4: ......

Страница 6: ......

Страница 7: ......

Страница 8: ......

Страница 9: ......

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

Страница 15: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ...above ...

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ...Brake Mount Assembly ...

Страница 47: ......

Страница 48: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 54: ...K5W 507 PD5 H505A ...

Страница 55: ...KD5 A501 Model No AG78301 402790 1M ...

Страница 56: ......

Страница 57: ...RAM P N AH04414R Double Reduction Wheel Drive SERVICE MANUAL ...

Страница 64: ......

Страница 68: ......

Страница 69: ...Component Data Sheets ...

Страница 70: ......

Страница 71: ...RAM P N AG35139 Air Cylinder ...

Страница 72: ......

Страница 73: ...RAM P N AG35139 A Air Cylinder ...

Страница 74: ......

Страница 75: ...RAM P N LB80045R 1 1 2 LUBRICATOR ...

Страница 76: ......

Страница 78: ......

Страница 79: ...RAM P N LB80040R 1 1 2 FILTER ...

Страница 81: ......

Страница 82: ......

Страница 83: ...RAM P N LB80050 REGULATOR ...

Страница 86: ......

Страница 87: ...RAM P N AG70252 ...

Страница 88: ......

Страница 89: ......

Страница 90: ...K5UR120ML Air Winch RAM WINCH HOIST 12 05 K5UR120ML Air Winch RAM WINCH HOIST 11 06 ...