Cooled Carousel 12 Plus Reaction Station

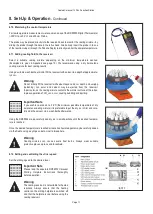

7.1. Assemble reflux head and cooling reservoir, so that they fit securely together.

Make sure that the reflux head is properly seated on the central pillar of the

reservoir.

7.2. Position cooled reservoir onto the stirring hotplate.

7.3. Place a magnetic stirrer bar into the reaction tube. Assemble Carousel

Reaction Tube and Easy-On PTFE Cap by screwing together. This process

requires a ¼ turn of the cap, hand tighten until the cap feels secure. Ensure

that the tube is properly located within the O-ring seal in the cap.

7.4. Fit a new Silicone Septa to the central hole in the cap, and ensure that the cap

valve is in the “open” position.

7.5. Place the assembled capped tube into the Carousel Reaction Station at the

required location, push the cap onto the connector pin, until the tube is fully

located in the reactor base.

7.6. Connect the central quick fit gas connector to the regulated inert gas supply

and switch the gas supply on.

7.7. If all gas connector positions are not in use, unused positions can be blocked

off with a Silicone Septa to ensure a satisfactory supply of gas to all reaction

tubes.

7.8. Select a suitable cooling mixture depending on the minimum temperature

desired. (Examples are given in Appendix see page 10). We recommend using

a dry ice/acetone cooling mixture for best cooling results.

7.9. Using a suitable wash bottle or similar fill the reservoir with solvent to a depth

of approximately 2cm.

7.10. Using the RR99908 scoop, carefully add dry ice in small portions until the

desired temperature is reached.

7.11. Set the stirrer speed on the stirring hotplate and switch stirrer on.

7.12. Once the desired temperature is reached air sensitive liquid reagents may be

carefully added via the Silicone Septa using a syringe under an inert atmo-

sphere.

7.13. Locate the optional lid onto the cooling reservoir. The lid has two adjacent slots

for the handle and pouring spout.

7.14. Once your synthesis is complete: turn off stirring; turn off gas supply and dis-

connect gas inlet; remove the lid; remove the Carousel reflux head from reser-

voir and place on the stand; the reaction tubes can now be removed.

7. Quick Start Guide

Page 7

Warning

The cooling reservoir is not suitable for heated reactions. Always

ensure that the heating control on the stirring hotplate is switched off

and that the hotplate is cool before using the cooling reservoir.

!

Important Note

Check that the reservoir can be removed from the top plate without

sticking before you fill the reservoir with a cooling mixture.

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,