Radijator Inženjering d.o.o, 36000 Kraljevo, Živojina Lazića

- Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150, http://www.radijator.rs

e-mail: [email protected]

47

8.

Boiler Operation and Maintenance

Before the start of operation be sure that the entire installation, specially the boiler is well

vented with no leaks.

Automation must not be switched on if you are not absolutely sure that all electrical

parts and conductors are not in contact with water.

The boiler is not ignited if you have not looked inside it and at the outside sides to

be sure there is no leakage of water from the boiler.

If there are direct valves from the boiler check whether they are open.

Check whether the safety devices on the hydro installation are correctly positioned and

whether they are in the function mode.

Only when the user is sure of the previous facts he can be start the ignition of the boiler.

Starting fire in boiler should be done according to the order of the following operations:

8.1. Operation start of the solid fuel boiler

The following procedure of boiler ignition and the start of automation system refers to the

situation of first firing of the boiler after the installing onto the hydraulic system or when the

boiler shuts down completely for thorough cleaning and and then it is re-started into the

operation, with a note that then some steps are skipped.

1. Check whether the boiler is properly connected to the hydraulic istem. Specially verify

whether the whole air is vented out of the boiler

2. Plug the mains supply into the network socket. Press the main switch of the automation

system. Then the display starts and is visible and after a few seconds there should appear

'OFF''.

3. On the hot gas pipe, as close as possible to the boiler, drill the hole for the boiler flue gas

probe. The opening should be in the upper zone so as not to produce the covering of the probe

with ashes. Also, check the flue damper is not hitting the probe. Without the temperature

probe for boiler flue gases the boiler can not work.

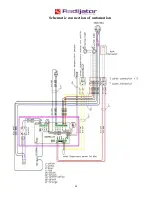

4. Inside the boiler there is a flap for directing the boiler flue gases in two regimes,'' the

working position“ and the „ignition“ regime. This flap is operated by means of the lever on

the side of the boiler. Move the lever in the direction towards the chimney. Now the flap is in

the position for ignition. It is the position - ,, open " -

in the picture „ Figure of the position of

flap“ which is on the next page.

Also, the flap on the outlet of the boiler, i.e. on the flue gas passage should maximum be

opened. It is the position in the Figure 1 „Figure of the position of the flap on the flue gas

pipe“

Flue gas flap on the outlet from the boilser is under the direct effect of the hot flue

gasses. Ako the boiler is operating for a long period of time this flap should be handled only

with protective equipment for hands because of the possibility of burns.

5. Open the lower door, then the grid door. Put some material for ignition on the grate bars as

paper and dry thin wood pieces. It is best to use chemical ignition units for firing being in the

form of cubes for ignition of firewood. Make fire manually and wait for the fire to be

intensive.