Installation Manual

COMBI - TA05A005.C0604

9

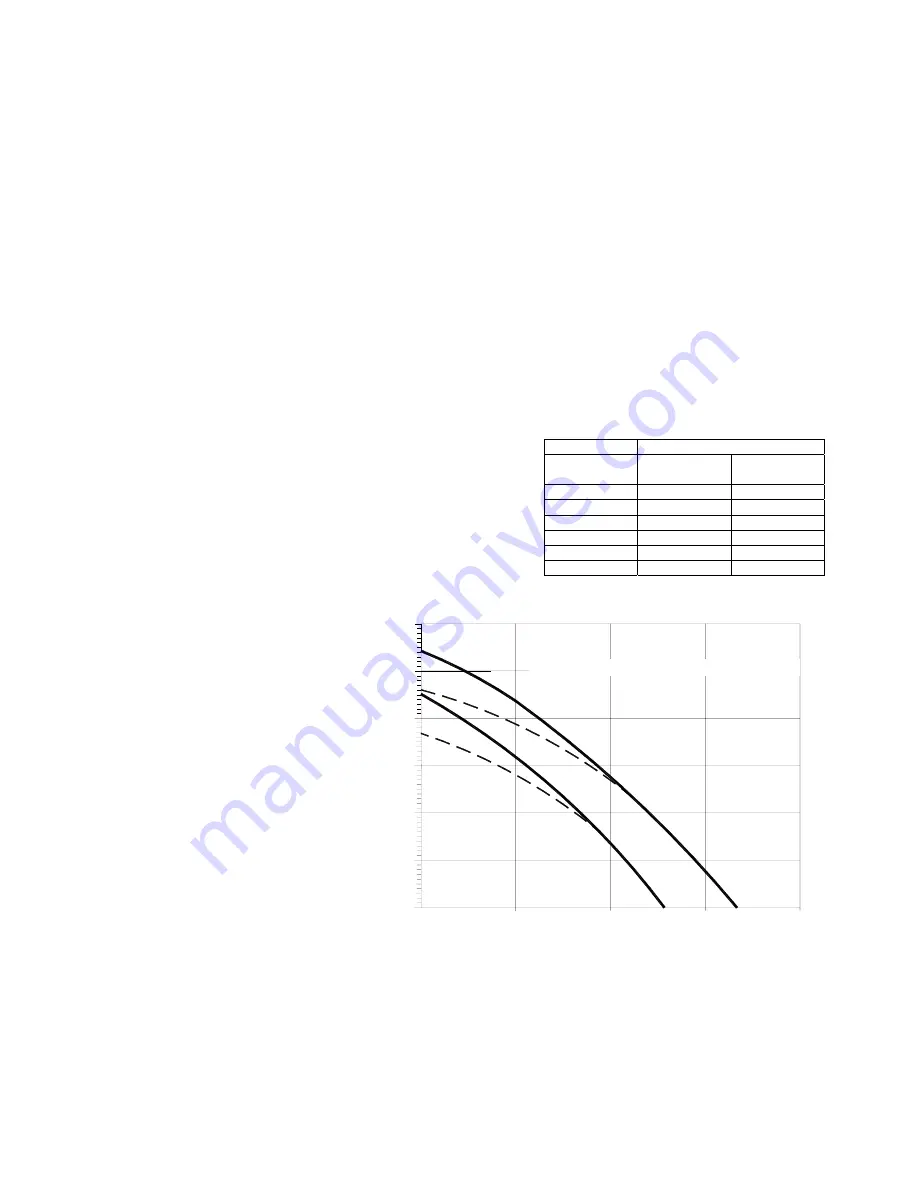

0

H

ead: m.c

.w.

Flow rete: lt/h

0

500

1000

1500

1

2

II

III

2000

3

4

6

5

GAS CONNECTIONS

The gas supply must be connected up by a corgi registered fitter.

The following standards must be complied with: UNICIG 7131/72 and UNICIG 7129/92 (of 21/04/93)

Before installing the boiler, make sure of the following:

the pipeline must be of an adequate section and length to carry the flow required and must be fitted with all safety devices and

measures prescribed by current norms;

before turning on the boiler make sure the type of gas which it is designed to run on is available;

the gas supply pressure must lie within the values shown on the boiler data plate (positioned on the inner side of front casing);

it is recommended that the gas supply pipeline should be checked for residual obstructions before installing the boiler;

where the internal gas supply pipe meets the boiler, the gas isolation cock supplied with the boiler must be fitted;

check thoroughly that the gas inlets and outlets are properly sealed.

conversion to allow the boiler to run on L.P.G. to natural gas or vice versa must be carried out by a qualified corgi registered fitter.

ANTI-FREEZE SYSTEM

The boiler is equipped with an anti-freeze system which comes into operation when the temperature falls to 5° C (heating sensor)

protecting the boiler down to an outside temperature of -2° C.

N.B: The system only comes into operation if the boiler is in the “ON” position (with MAIN SWITCH turned to SUMMER or

WINTER position) and the gas supply turned on.

FOR THE INSTALLER

For boilers installed outdoors, where the temperature may drop below -2°

degrees Centigrade, the system should be filled with antifreeze liquid by an

authorised technician and a set of electrical heating elements should be

fitted.

ADVICE FOR THE SERVICE TECHNICIAN

If the boiler is out of service because it is

frozen, check that no parts have been

locked in position by ice before putting it

into operation.

It is advisable to empty the boiler and the

system if it will not be used for a long

period.

Recommended percentage of glycol for

temperatures down to - 8°C is 20%.

The antifreeze liquid used must be of a

good make and in a solution which has

already been diluted to avoid the risk of

uncontrolled dilution.

Antifreeze Temperature

Ethylene glycol

(%) volume

freezing point

(°C)

boiling point

(°C)

10 -

4 101

20 -10 102

30 -

17 104

40 -

27 106

50 -

40 109

60 -

47 114

CIRCULATING PUMP SPECIFICATIONS

Содержание RBS 20 E

Страница 2: ......

Страница 20: ...Installation Manual COMBI TA05A005 C0604 17 RBS 20 E WIRING DIAGRAM...