32

R1K 24 /B - RAD - ING - Manuale - 1507.1 - R2 G

2 Ve

rif

ic

a

e t

a

ra

tur

a del

va

lo

re

di

CO

2

_

M

IAH

4

_

R2

K

_

E

N

2. FIRST START-UP

SUPPOR

T

C

ENTRE

2.1.3. CO2 VALUE CHECK AND

CALIBRATION

WARNING

The CO

2

value should be checked with

the casing assembled, while the gas valve should be

adjusted with the casing open.

To check and calibrate the CO

2

value to minimum

and maximum heating power proceed as follows:

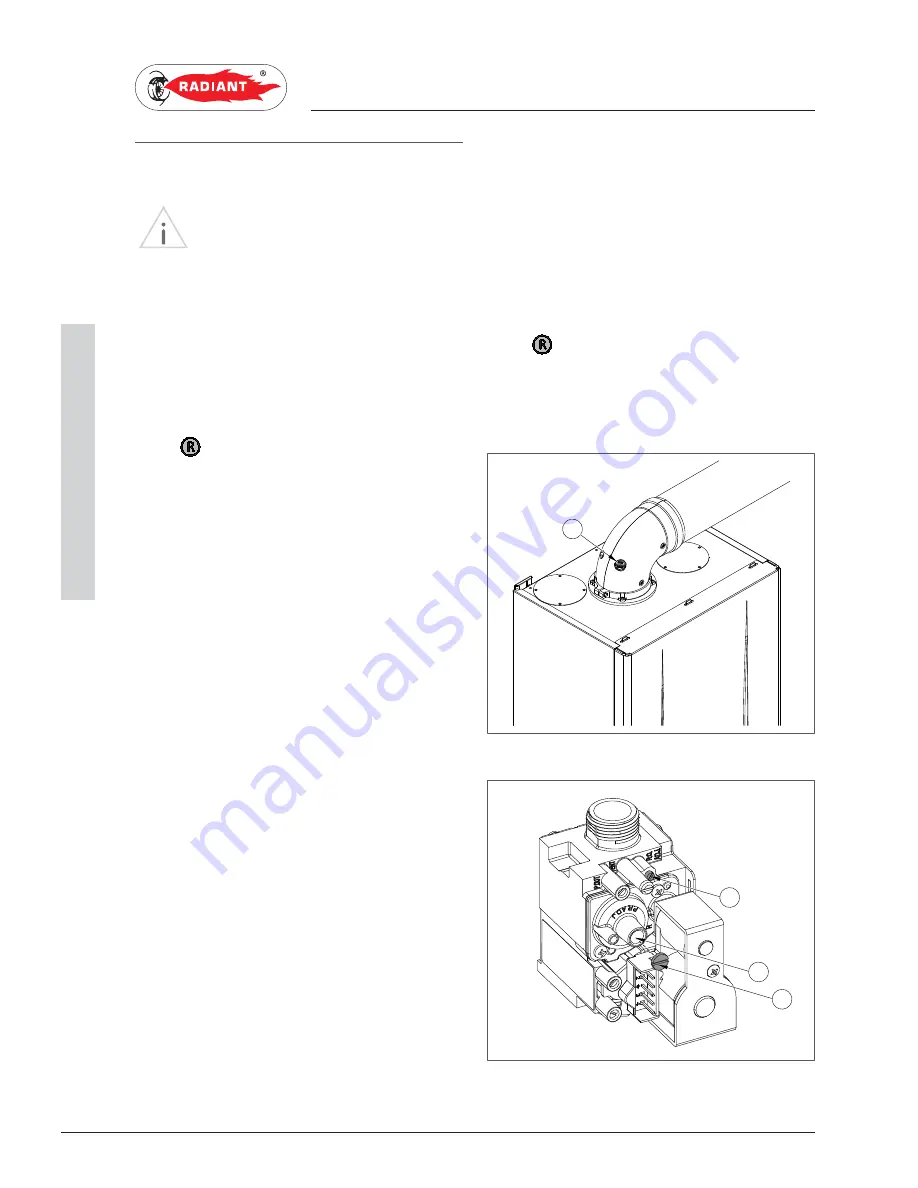

FOR MAXIMUM HEATING POWER

› Activate the chimney sweep function holding the

key ‘

’ for 7 seconds.

› Insert the fumes analyser probe in the suitable

‘PF’ fumes inlet (fig. 1), then make sure that

the CO

2

value complies with the requirements

indicated in chapter “Technical data”, otherwise

adjust using screw ‘1’ (fig. 2) of the gas flow

adjuster. To increase the CO

2

value, turn the

screw anti-clockwise and vice-versa if you want

to decrease it.

› After each adjustment variation on screw ‘1’

(fig. 2) of the gas flow adjuster you have to wait

for the boiler to stabilize itself to the set value

(about 30 seconds).

FOR MINIMUM HEATING POWER

› Access parameter ‘P10’ following the procedure

described in chapter “Parameters accessing

and programming” and stay in edit mode until

the calibration is completed (the maximum time

before forced exiting the edit mode is 7 minutes.

› Make sure that the CO

2

value complies with

the indications in “Technical data”, otherwise

unscrew the protection screw ‘A’ (fig. 2) and

adjust using a 4 Allen wrench the screw ‘2’ (fig.

2) of the Off-Set adjuster. To increase the CO

2

value, turn the screw clockwise and vice-versa

if you want to decrease it.

› Once completed the adjustment, tighten the

protection screw ‘A’ (fig. 2) on the Off-Set

adjuster.

› Exit parameter ‘P10’ following the procedure

described in chapter “Parameters accessing

and programming”.

› Activate the chimney sweep function holding the

key ‘

’ for 7 seconds.

› Make sure that the CO

2

value did not change

to maximum, if changed repeat the calibration

described in the previous paragraph.

PF

1

2

A

fig. 1

fig. 2