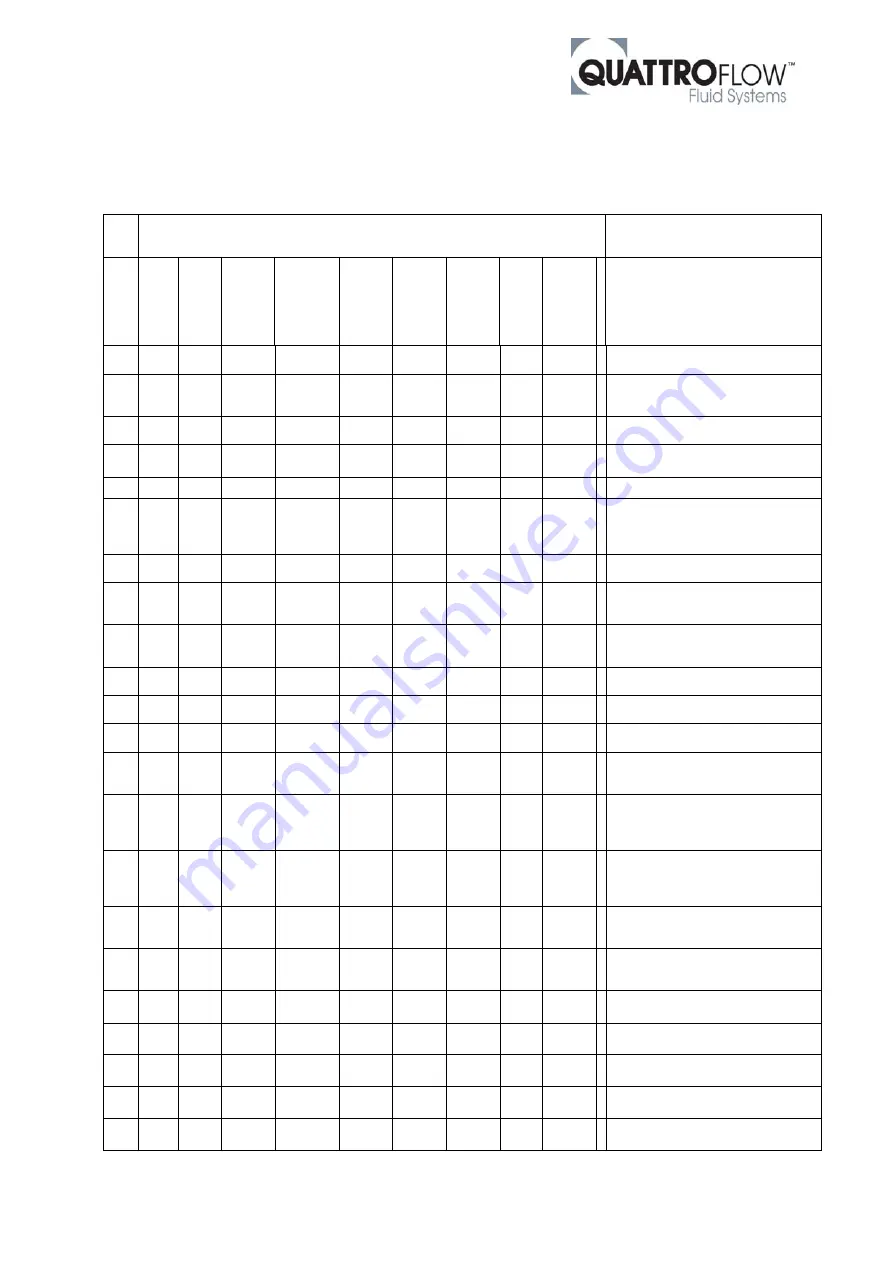

QF1200S; edition 2016-05; page 19 of 24

5. Operating troubles, causes and remedial action

(Troubleshooting)

No.

Operating troubles

Causes and remedial

action

Pump

does

not

start

Pump

does

not

prime

Delivery

is not

ob-

tained

or

reduced

Pressure

head is

not

obtained

Irreg-

ular

pump

delivery

Pump

oper-

ates

noisily

Pump

is

leaky

Motor

gets

too

warm

Display

show

Error

code

1

X

X

The screws of the pump-chamber

maybe not tightened enough. Fix it!

2

X

Check the direction of flow showed by

the arrow on the pump, in case of

wrong way, turn the pump head.

3

X

X

X

Check suction pipeline and TC- seals

for tightness.

4

X

X

X

X

Check suction head-increase suction

line cross section.

5

X

X

X

Check viscosity of liquid pumped.

6

X

X

Check pump speed. Control speed of

drive motor. Check voltage and

frequency and the fuse (6,3A T in the

control box)

7

X

X

X

Avoid air inclusions in the liquid to be

pumped.

8

X

X

Check pressure head-open valve in

discharge line completely, remove

obstruction in discharge line.

9

X

Pressure line completely or partly

clogged, diaphragm maybe broken,

change diaphragm!

10

X

The diameter of the pipes in suction or

pressure line are too small.

11

X

Check the coupling halves. They must

be fixed with 1,5 mm space (see 4.2.2.)

12

X

Check longitudinal play of coupling rod

pins. The spider might be worn.

13

X

X

X

Check whether foreign bodies in pump.

Disassemble pump, remove foreign

bodies, replace defective parts.

14 X

X

X

Pump stopped by the thermal circuit

breaker. Please allow the motor to cool

down – please reduce the power

consumption.

15 X

X

Bearings are worn or defective

Disassemble pump, replace the shaft –

bearing – cap unit (PSKITWLC123 or

PSKITWLC125).

16

X

The valves are dry (e.g. not in use for a

long time), deformed or worn. Change

valve or wet the pump.

17

X

The diaphragm is burst ( the discharge

pressure was too high) – replace it

PSKITQ12.

18

X

X

X

X

O–rings between valve plate and pump

housing are defective PSKITQ12.

19

X

Align coupling accurately

20

X

X

The clamping ring screw got loose –

fixe it! See chapter 4.1.2. (drawing 12)

21 X

X

Parameters of the control panel are

wrong – check basic settings.

22

X

Pump after SIP cooled down too fast –

slow cooling with room temperature