9

Troubleshooting

Warning:

Electrocution hazard! Before working on any live elements, pull out the mains plug

respectively switch off the main installation switch!

If a malfunction occurs which might be detrimental to the safety of the users, and

which cannot be eliminated without delay, the operator must be informed and if required

the installation shall be taken out of operation. The installation must be repaired as

soon as possible.

Note:

Every troubleshooting procedure which is carried out must be entered into the control booklet!

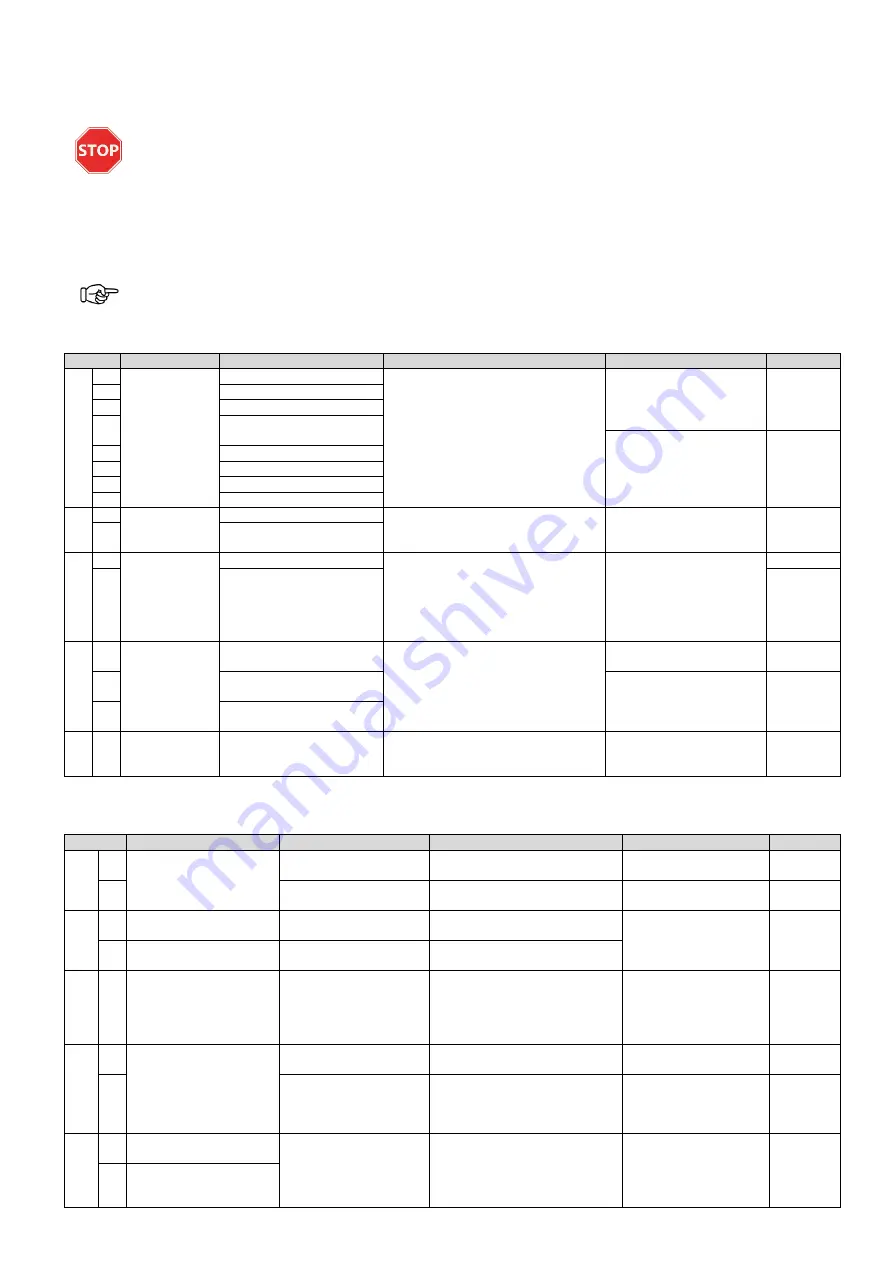

9.1

Drive mechanism

No.

Description

Cause

Elimination

Checking time

Reaction

E1

03

Encoder

Channels A+B lost

Check the encoder connection.

Check the motor cable.

The sense of rotation of the motor is not

in compliance with the rod assembly.

The door is blocked.

Check if a jumper has been inserted on

X106.

During run.

H

04

Short-circuit A+B

05

Dysfunctions

06

Motor cable plugged in

uncorrectly

Prior to start-up.

H

07

No channel A

08

No channel B

09

No channel A+B

10

Short-circuit A+B

E2

01

Motor current

Current too high

Check the motor cable.

Check if a jumper has been inserted on

X106.

Prior to star-up.

H

02

Current too low

Jumper missing

E3

01

Cushioning

Test failed once

Switch the drive unit to the MANUAL

operating mode and carefully check if the

door closes in a cushioned manner. If not:

replace the hardware. If yes:

check/correct the friction of the door leaf

and the prestressing of the closing spring.

Prior to the closing motion,

after start-up, and

subsequently every 24 h.

W

02

Test failed twice.

Damping defective.

F

E4

01

Reference

switchr

Detected in the open

position.

Check the connection and the switching

point of the reference switch.

The reference switch must be activated

in the closed position (switching contact

open).

Open position.

F

02

Not detected in the closed

position.

Prior to the first setting-up

run.

A

03

Not detected in open

position.

E5

00

Power limitation

Overload of the control. The

maximum power is restricted.

Check/correct the friction of the door leaf

and the pre-stressing of the closing

spring.

Permanent.

A

9.2

Operating

No.

Description

Cause

Elimination

Checking time

Reaction

E10

01

Fullteach required

Parameter Ao, Rod, Invers

or dAxis changed.

Carry out a teach.

Upon changing the

drive unit configuration.

H

02

Minimum opening angle

has not been reached.

Check the locking/electric lock.

During Teach.

H

E11

01

Halfteach required

(Opening)

Parameter Vo changed.

Carry out a complete and

unhindered .opening cycle.

Upon changing the

motional parameters.

W

02

Halfteach required

(Closing)

Parameter Vc or FSlam

changed.

Carry out a complete and

unhindered .closing cycle.

E12

03

Excessively high current

consumption during Teach

in the open position (> 5 A)

Drive unit pushes against

the open position stop

piece or an obstacle. The

spring tension is possibly

too high.

Reduce the opening angle Ao.

Reduce the spring tension.

Open position Teach 3

(E11).

F

E14

01

Locking/electric lock

The door leaf got caught in

the locking/electric lock.

Check the function of the locking/

electric lock.

When opening from a

closed position.

H

02

The inverted operation has

no locking, or the

interlocking force Fch has

not been programmed.

Program/increase the interlocking

force Fch.

At the end of the teach-in

procedure.

W

E15

01

Obstacle in opening

direction

Too many successive

obstacles have occured.

Examine the installation.

Remove the obstacle.

Move the door leaf to the target

position.

Permanent.

H, A

Restart

after 60 s

02

Number of obstacles within

60 seconds