Quadra-Fire • QVI-30FB • 2020-900 Rev. H • 9/07

16

Step 2. Positioning, Leveling, and

Securing the Insert

• Place the insert into position.

• Level the insert from side to side and from front to back.

Use the leveling legs if necessary to set each corner of

the base. The levelling legs are mounted behind the fan

cover plate. For location of fan cover plate, see Figure

11 on page 17.

!

!

Step 3. The Gas Control System

WARNING: THIS UNIT IS NOT FOR USE WITH

SOLID FUEL.

These models use a standing pilot ignition type of gas con-

trol system.

Standing Pilot Ignition System

This system includes millivolt control valve, standing pilot,

thermopile/thermocouple flame sensor, and piezo ignitor.

WARNING: 110-120 VAC MUST NEVER BE

CONNECTED TO A CONTROL VALVE IN A

MILLIVOLT SYSTEM.

STANDING PILOT

Figure 6. Gas Controls System

Step 4. The Gas Supply Line

NOTE: Have the gas supply line installed in accordance

with local building codes by a qualified installer

approved and/or licensed as required by the locality.

(In the Commonwealth of Massachusetts installation

must be performed by a licensed plumber or gas

fitter).

NOTE: Before the first firing of the fireplace, the gas

supply line should be purged of any trapped air.

NOTE: Consult local building codes to properly size

the gas supply line leading to the 1/2 inch (13 mm)

hook-up at the unit.

This gas fireplace is designed to accept a 1/2 inch

(13 mm) gas supply line. To install the gas supply line:

• A listed (and Commonweatlh of Massachusetts approved)

1/2 inch (13mm) tee-handle manual shut-off valve and a

listed flexible gas connector are connected to the 1/2

inch (13mm) inlet of the control valve.

NOTE:

If substi-

tuting for these components, please consult local codes

for compliance.

• Locate the gas line access hole in the outer casing of

the fireplace.

• Insert the gas supply line through the gas line hole and

connect it to the shut-off valve.

• When attaching the pipe, support the control so that the

lines are not bent or torn.

• After the gas line installation is complete, all connec-

tions must be tightened and checked for leaks with a

commercially-available, non-corrosive leak check solu-

tion. Be sure to rinse off all leak check solution following

testing.

WARNING: DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

!

Figure 7. Gas Supply Line

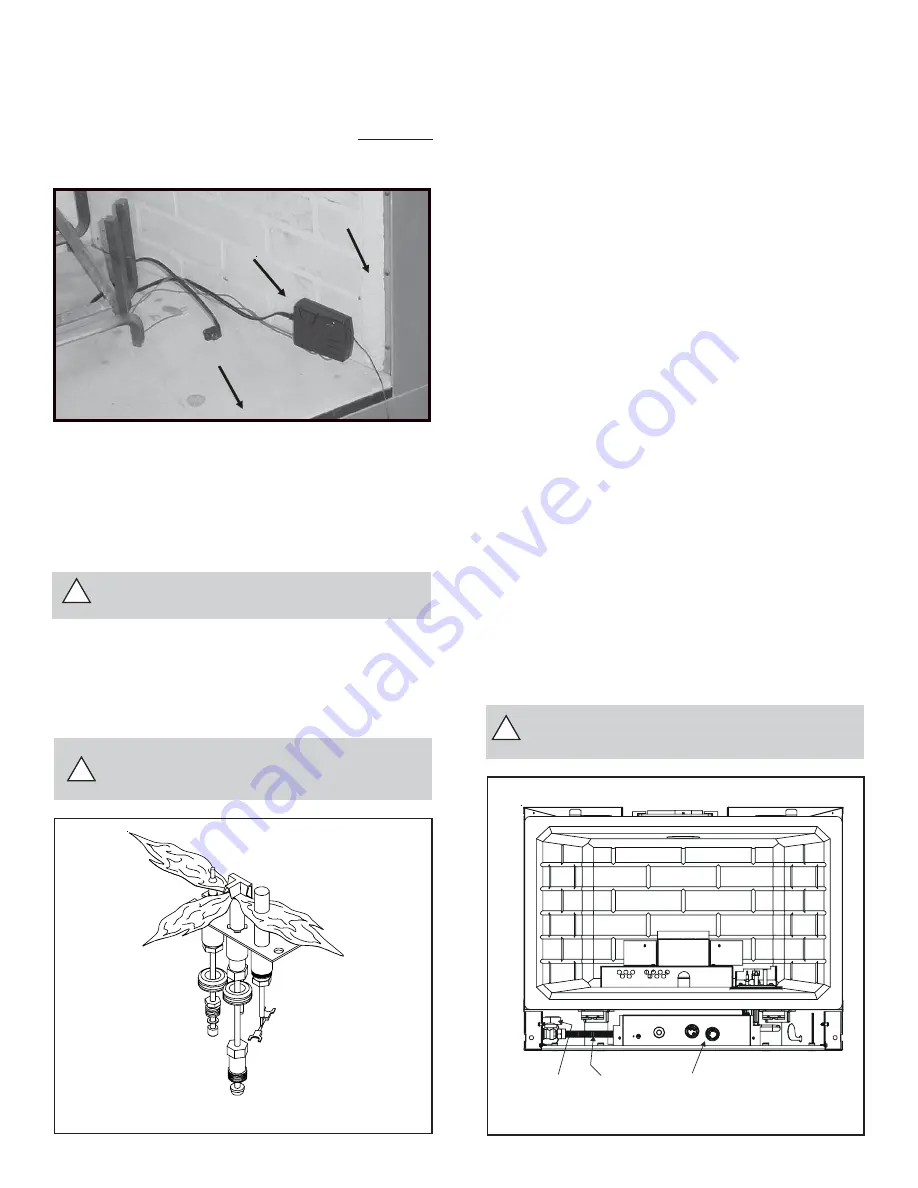

Remote Control

The receiver for the remotes must be installed

BETWEEN

the base pan of the insert and the firebox of the wood-burn-

ing fireplace (see photo below).

EXISTING BOTTOM

OF FIREPLACE

REMOTE

RECEIVER

UNIT

EXISTING SIDE

REFRACTORY

GAS

SHUT-OFF

FLEXIBLE

GAS LINE

CONTROLS