Page 2

Quadra-Fire · Castile Gas Stove · 7023-111E ·

September 1, 2008

and Welcome to the Quadra-Fire Family

!

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability,

and performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation

of our stoves, inserts and fireplaces. And yet we are old-

fashioned when it comes to craftsmanship. Each appliance

is meticulously fabricated and gold and nickel surfaces are

hand-finished for lasting beauty and enjoyment. Our pledge

to quality is completed as each model undergoes a quality

control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

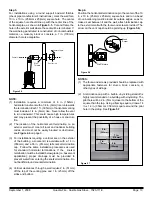

SAMPLE OF SERIAL NUMBER / SAFETY LABEL

LOCATION: HANGING ON A CHAIN ON BACK OF APPLIANCE

This appliance equipped only for altitudes 0-2000’ (0-610m) in USA; and in Canada for altitudes of 0-4500’ (0-1370m). In USA for Altitudes above 2000’, the vent configuration,

orifice, or combination of both may need to be changed. See Owner’s Manual for information on making these changes.

Cet appareil est équipé pour les altitudes de 0-2000’ (0-610m) aux États-Unis; et au Canada pour les altitudes de 0-4500’ (0-1370m). Pour les altitudes au dessus de 2000’ aux

États-Unis, la configuration du ventilateur, son orifice ou les deux peuvent possiblement avoir à être changé. Voyez le manuel du propriétaire pour les informations sur ces

changements.

This appliance must be installed in accordance with local codes, if any (and Commonwealth of Massachusetts approved); if none, follow the National Fuel Gas Code. ANSI Z223.1

or Canadian Installation Codes, CAN/CGA-B149. Install and use only in accordance with manufacturer’s installation and operating instructions. NOTE: Have the gas supply line installed

in accordance with local building codes by a qualified installer approved and/or licensed as required by the locality. (In the Commonwealth of Massachusetts, installation must be performed by

a licensed plumber or gas fitter.)

Cet appareil doit être installé en accord avec les codes locaux, s’il-y-a lieu (et approuvé par dans la République de Massachusetts); sinon lisez ANSI Z223.1/CAN 1-B149. Installez

et utilisez en accords avec les instructions d’installation et d’opération du manufacturier. REMARQUE: Le conduit gaz doit être installé conformément aux codes de construction

locaux. L'installation doit être effectuée par un technicien qualifeé et/ou muni d'une licence de manière à respecter les règlements municipaux. (Dans la République de Massachusetts,

l'installation doit être effectuée par un plombier ou un installateur d'appareils à gaz agrée.)

Thermal Efficiency / Efficacité thermique*

81.43% NG (blower on / avec ventilateur allumé)

82.75% LP (blower on / avec ventilateur allumé)

* With Maximum horizontal length. / Avec longueur horizontale maximum.

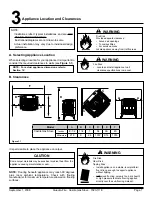

MINIMUM CLEARANCES TO COMBUSTIBLES / ESPACE MINIMUM AUX COMBUSTIBLES

Minimum clearances required from combustible construction for all appliance surfaces.

Espaces minimum exigés de la construction combustible aux surfaces de l’appareil.

HEARTH: A non-combustible hearth pad is not required. However, the floor beneath the stove must be stable, level, and strong enough to support the stove without a tipping hazard.

CHEMINÉE: Un coussinet non-combustible de cheminée n’est pas exigé. Cependant, le plancher en dessous du poêle doit être droit, à niveau et assez fort pour supporter le poêle

sans le hasard de basculer.

APPROVED FOR CANADA AND USA TO:

ANSI Z21.88b-2003 / CSA 2.33b-2003 Vented Gas Fireplace Heaters, and

applicable sections of UL307b Gas Burning Heating Appliances for Manufactured

Homes and Recreational Vehicles, CAN/CGA 2.17-M91 “Gas Fired Appliances

for use at High Altitudes.” This appliance is manufactured for operation with

Natural Gas.

For conversion to propane Manufacturer’s Part #LPK-MB and instructions must

be used. This appliance may be installed in a bedroom or bedsitting room; in

Canada remote thermostat installation is required.

APPROUVÉ POUR LE CANADA ET LES ÉTATS-UNIS:

ANSI Z21.88b-2003 / CSA 2.33b-2003 Fournaises au Gaz avec Ventilation,

et les sections applicable de UL 307b Appareils de Chauffage Au Gaz pour

les Maisons Mobiles et les Véhicules Motorisés, CAN/CGA 2.17-M91 “Gas

Fired Appliances for use at High Altitudes”. Cet appareil est manufacturé

pour l’opération avec le Gaz Naturel. Pour une conversion au gaz propane

les pièces du Manufacturier #LPK-MB et ses instructions doivent être utilisées.

Cet appareil peut être utilisé dans une chambre à coucher ou salle de séjour;

au Canada, l’installation d’un thermostat à distance est exigée.

Date of Manufacture / Date du Manufacturier

2008

2009

2010

Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Jan

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L’ÉTIQUETTE

Made in U.S.A. / Fait Aux États-Unis

7023-112

P.4.1-02 Canada Minimum pipe

(P.4.1-02 Le canada tuyau minimum)

57.33% NG / 56.41% LP

F

AN TYPE VENTED CIRCULATOR / VENTILATEUR CIRCULATOIRE

Optional Blower Kit #BK-GAS / Le Souifleur Optionel Kit #BK-GAS

120Vac, 60Hz., 12 Amperes or less (ou moins)

Route power cord away from unit. / Éloignez le fil électrique de l'appareil. Do not route

power cord under or over stove. / Ne pas faire passer le fil électrique au dessus ou en dessous de l'appareil.

0-2000 FT’

0-2000FT

Input Rate on “HI” (BTU/Hr)

31,000

30,000

Puissance Évaluée à “HI” (BTU/Hr)

Input Rate on “LO” (BTU/Hr)

22,000

23,000

Puissance Évaluée à “LO” (BTU/Hr)

Maximum Output (BTU/Hr)**

20,943

21,519

Puissance Maximum (BTU/Hr**

Main Burner Orifice

.106

.063

Orifice du Brûleur Principal

Minimum Inlet Pressure (Inches W.C.)

4.5”

11”

Pression Minimum de la Valve (pouces W.C.)

Maximum Inlet Pressure (Inches W.C.)

7.0”

14”

Pression Maximum de la Valve (pouces W.C.)

Manifold Pressure on “HI” (Inches W.C.)

3.5”

10”

Pression du Collecteur d’ Échappement à “HI” (pouces W.C.)

**Max Venting, Blower On

**Ventilation Maximum, Ventilateur Allumé

For use with Propane

Usage Au Gaz Propane

For use with Natural Gas

Usage Au Gaz Naturel

A. Side of stove top to side wall

8-1/2 in. (216mm)

Du côté du poêle au côté du mur

B. Back of stove to back wall (air shield)

1/4 in. (6mm)

Le contrôle arrière au mur arrière (écran)

C. Corner of stove top to side wall

1 in. (24mm)

Du coin du dessus du poêle au mur de côté

D. Minimum Alcove Height

54 in. (1372mm)

Hauteur minimum du plancher au plafond

E. Maximum Alcove Depth

36 in. (914mm)

Profondeur maximum de l'alcove

F. Minimum Alcove Width

40 in. (1016mm)

Largeur minimum de l'alcove

D

A

A

E

A

F

A

B

C

C

SAMPLE

VENTED GAS FIREPLACE HEATER

N

OT FOR USE WITH SOLID FUEL

Serial No / Numéro du

Report No. / Rapport Numéro

061-S-64-5

FOURNAISE AU GAZ AVEC

VENTILATION

NE PAS UTILISER AVEC LE COMBUSTIBLE SOLIDE

MODEL / MODÈLE: CASTILE GAS STOVE

007

1445 North HIghway

Colville, WA 99114

www.quadrafire.com

US

Portland

Manufactured Date

Serial Number

Model Name

Test Lab & Report No.

Barcode