39

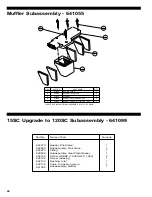

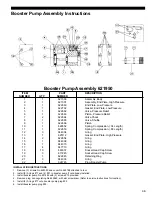

382370

622849

623014

623015

623334

623515

623520

623647

632424

624759

624760

624761

624762

624763

624764

624765

624766

624767

624768

629251

629252

Tool box

Assembly tool

Assembly tool, press. Foot nut

Assembly tool, trigger lock

Assembly tool, pressure hydraulic & front enclosure

Assembly tool, pressure foot nut

Assembly tool, bulkhead removal

Assembly tool, depth stop

Removal tool, valve

Slide hammer puller

Assembly fixture

Wrench, spindle bearing locknut

Bearing installer

Removal tool, feed control valve

Removal tool, pilot valve

Arbor press fixture

Valve installation tool

Wrench, feed control valve

Tee wrench, foot body

Tool, 136SC pull rod bushing

Tool, 15/120SC pull rod bushing

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

QTY.

NAME OF PART

PART NO.

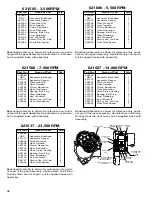

MAINTENANCE KIT - 621953

SYMPTOM

Air motor and/or clamp and feed func-

tions do not start when trigger is de-

pressed.

Air motor does not run when trigger is

depressed, but feed and clamp functions

properly.

Air motor “idles” when trigger valve is

released.

Motor runs, but clamp & feed functions do

not start.

Motor runs, clamps but doesn’t feed.

Lunge during feed or variation in feed

rate.

Tool doesn’t retract at end of feed stroke.

Tool retracts shortly after trigger de-

pressed.

Tool “pulses” on retract (rapid ‘’feed

retract-feed retract”).

REASON

Trigger or pilot valves clogged with for-

eign matter.

Gears damaged or jammed with debris.

Foreign matter in motor inlet.

Broken rotor blades, rotor or gear bear-

ings.

Pilot valve or retract and dwell valve sticky

(not fully reset), or bad O-ring.

Leaking O-ring on air motor rear bear-

-ing support.

Unclamp check valve doesn’t shift when

trigger is depressed.

Feed control valve “closed”

Defective feed control cylinder.

Dwell valve seated too tightly.

Retract and dwell valve doesn’t shift.

Depth control adjusted out of the max.

range of the tool.

Dwell valve opened too far off of seat.

Damaged O-rings on retract and dwell

valve.

SOLUTION

Remove trigger and pilot valves (sepa-

rately) and inspect for rust or debris. In-

spect O-rings and replace if necessary,

With air line disconnected check for free

spindle rotation with hex key wrench in end

of spindle. Remove backhead, clean and

inspect gears for damage.

Remove motor and clean debris from mo-

tor inlet.

Remove motor and inspect rotor blades

and bearings. Replace if necessary.

Remove and check valves for debris and

free movement of spool. Inspect O-rings,

lubricate and reassemble.

Remove and inspect O-rings. Replace if

necessary and reassemble.

Remove unclamp check valve and inspect

for debris, free movement and damaged

O-rings. Lubricate and reassemble.

Back off feed control valve counter-

clockwise until feed commences.

Replace feed control cylinder.

Back dwell valve off from seat 1/8 turn to 1

& 1/2 turn.

Remove retract and dwell valve and in-

spect for debris, free movement and dam-

aged O-rings. Lubricate and reassemble.

Readjust depth control nut within the feed

stroke of the tool (ref.: 1.10 max. stroke).

Turn dwell valve clockwise (should be 1/8

to 1&1/2 turns of seat).

Remove retract and dwell valve, in-

spect O-rings and replace as necessary.

Lubricate and reassemble.

TROUBLE SHOOTING

Содержание 120SC - 225

Страница 2: ...2 ...

Страница 8: ...8 ...

Страница 9: ...9 ...

Страница 10: ...10 ...

Страница 11: ...11 ...

Страница 12: ...12 ...

Страница 13: ...13 ...

Страница 14: ...14 ...

Страница 15: ...15 ...

Страница 16: ...16 ...

Страница 17: ...17 ...

Страница 18: ...18 ...

Страница 19: ...19 ...

Страница 20: ...20 ...

Страница 21: ...21 ...

Страница 22: ...22 ...

Страница 23: ...23 ...

Страница 24: ...24 ...

Страница 33: ...33 ...

Страница 34: ...34 ...

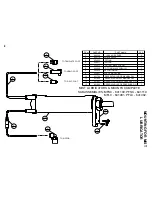

Страница 36: ...36 PRESSURE FILL MIST LUBRICATOR Note x Upper number is item x Lower number is quantity required ...

Страница 37: ...37 MANUAL FILL MIST LUBRICATOR Note x Upper number is item x Lower number is quantity required ...

Страница 40: ...40 CooperTools 7007 Pinemont Houston Texas 77040 Phone 713 462 4521 Fax 713 460 7008 www cooperindustries com ...