3

• Before the tool is connected to the air supply, the throttle should

be checked for proper operation (i.e., throttle valve moves freely

and returns to closed position).

• Before removing a tool from service or changing drill bits, make

sure the air line is shut off and drained of air. This will prevent the

tool from operating if the throttle is accidently engaged.

• Cutting tools used with these drill motors are sharp. Handle them

carefully to avoid injury.

• The collet and mandrel must be inserted into a properly sized

pre-drilled hole before starting the tool. An improperly sized pre-

drilled hole prevents the mandrel from engaging the collet and

could result in slippage of the tool. An improperly selected collet

and mandrel can also result in slippage of the tool.

Drilling or other use of this tool may produce hazardous fumes

and/or dust. To avoid adverse health effects utilize adequate

ventilation and/or a respirator. Read the material safety data

sheet of any cutting fluids or materials involved in the drilling

process.

Some non-ferrous metal chips (or dusts) are combustible. Ex-

amples: Aluminum, magnesium, Titanium, and Zirconium. See

the material safety data sheets for combustibility of materials

drilled. Never collect spark generating material with combustible

material. Examples: Collecting both steel and aluminum or steel

and titanium.

Quackenbush drills are often used with lubricant or cooling

systems which must be properly maintained to avoid leakage.

Failure to do so can result in serious injuries from slipping on oily

surfaces.

For your safety and the safety of others, read and understand

the safety recommendations and operating instructions be-

fore operating any drill motor.

Always wear protective equipment:

For additional information on eye protection, read the latest edition

of ANSI Z87.1, Occupational and Educational Eye and Face

Protection. This standard is available from the American National

Standards Institute, Inc., 11 West 42nd Street, New York, N.Y.

10036.

Hearing protection is recommended in high noise areas (above

85dBA). Close proximity of additional tools, reflective surfaces,

process noises, etc., can contribute substantially to the sound

level experienced by the operator.

Follow good machine shop practices. Rotating shafts and moving

components entangle and entrap, and may result in serious

injuries. Never wear long hair, loose-fitting clothes, gloves, ties,

or jewelry when working with or near a drill of any type.

Quackenbush drills are designed to operate on 90psig (6.2 bar)

maximum air pressure using the proper hose. Excessive air

pressure increases the loads and stresses on tool parts and drills,

and may result in breakage. The installation of a filter-regulator-

lubricator in the air supply line ahead of the tool is highly recom-

mended.

Safety Recommendations

!

Do not wear loose fitting clothes,

long hair, gloves, ties or jewelry.

WARNING

CAUTION

!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING

!

Impact resistant eye protection

must be worn while operating

or working near this tool.

CAUTION

!

WARNING

!

Wear respirator where

necessary.

CAUTION

!

CAUTION

!

Slip and fall hazard.

Lubricant and coolant systems must

be properly maintained to avoid

leakage.

Hoses must be organized and care

taken to avoid tripping.

Содержание 120SC - 225

Страница 2: ...2 ...

Страница 8: ...8 ...

Страница 9: ...9 ...

Страница 10: ...10 ...

Страница 11: ...11 ...

Страница 12: ...12 ...

Страница 13: ...13 ...

Страница 14: ...14 ...

Страница 15: ...15 ...

Страница 16: ...16 ...

Страница 17: ...17 ...

Страница 18: ...18 ...

Страница 19: ...19 ...

Страница 20: ...20 ...

Страница 21: ...21 ...

Страница 22: ...22 ...

Страница 23: ...23 ...

Страница 24: ...24 ...

Страница 33: ...33 ...

Страница 34: ...34 ...

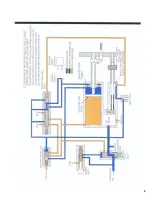

Страница 36: ...36 PRESSURE FILL MIST LUBRICATOR Note x Upper number is item x Lower number is quantity required ...

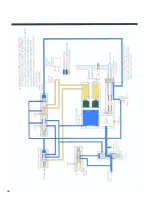

Страница 37: ...37 MANUAL FILL MIST LUBRICATOR Note x Upper number is item x Lower number is quantity required ...

Страница 40: ...40 CooperTools 7007 Pinemont Houston Texas 77040 Phone 713 462 4521 Fax 713 460 7008 www cooperindustries com ...