User Manual

Q-Tech Q-P019 -

Electric Airless Spray Pump

16

6. Replace the packings, glands, o-rings

and check balls with the new parts

from the rebuild kit. Strictly follow the

exact order and orientation.

7. Replace piston and thread on the

packing nut. After resistance from the

disc springs is felt, tighten the packing

nut a further 3/4 turn.

MOTOR MAINTENANCE

Every 50 hours of operation blow

compressed air through the motor while

running at no load to clean out

accumulated dust. (If operating in

especially dusty conditions, perform this

operation more often.)

LUBRICATION

– The gear case grease

may be changed every 200 hours of

operation. This is best entrusted to a

qualified repair technician.

THE CARBON BRUSHES

The carbon brushes are a normal wearing

part and must be replaced when they

reach their wear limit. When the brushes

are worn to a length of 1/4", they should

be replaced as a set.

TO CHANGE THE BRUSHES

1. Unplug the machine.

2. Remove the brush cap with a slothead

screwdriver

3. Remove the brush.

4. Install new brushes in reverse order

and replace covers

Содержание Q-P019

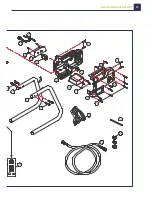

Страница 19: ...www aristospray com 19 WIRING ...

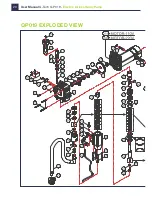

Страница 20: ...User Manual Q Tech Q P019 Electric Airless Spray Pump 20 QP019 EXPLODED VIEW ...

Страница 21: ...www aristospray com 21 ...