Tech Support: 1-888-989-7873

PURE WATER TREATMENT, INC.

Page 7

1.

Turn off the main water shutoff valve.

2.

Next, open all plumbing fixtures in the house including all outside faucets in order to

drain the lines of all water possible.

3.

Cut and remove a section of the main incoming water line near where the system is to

be installed. Allowing this line to drain thoroughly.

4.

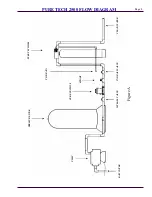

Install

PURE TECH 250

. See page 28 for installation

5.

Remove the yoke (or optional bypass valve) from the back of the tank valve by loos-

ening the two small stainless steel clamps on either side of the rear valve assembly,

that holds it in place. Then simply pull it off the back of the valve. Now that you have

the yoke or bypass valve removed, follow the directions below to make them ready to

install on the valve.

6.

INSTRUCTIONS FOR USING A YOKE. If you have a standard Noryl Plastic yoke,

it will have two ¾" or 1" male thread nipples, (one inlet & one outlet). You will need

to buy two ¾" or 1" Female thread adapters to whatever type and size of piping you

are plumbing the system to.

7.

INSTRUCTIONS FOR USING A BYPASS. If you are using our optional ¾" or 1"

brass bypass valve, you will need to purchase two ¾" or 1" Male thread adapters to

whatever type and size pipe you are plumbing to.

8.

If you are going to use copper piping and be soldering joints, we do not recommend

applying intense heat, to your new valve/meter assembly. We always recommend that

you remove the yoke or bypass from the valve assembly, and attach your plumbing

adapters to the yoke or bypass away from the valve. This simple step will ensure that

you are not applying any heat as you solder or pressure as you tighten the adapters

onto the yoke/bypass, while they are mounted on the valve body itself.

9.

Another tip if you are using copper adapters. Always solder a 3" to 5" piece of copper

pipe into each of the two pipe adapters away from the valve, then let them cool off

before threading each one onto the yoke or bypass valve.

10.

After they cool off, apply Teflon tape to the male threads of the Noryl yoke, (or onto

the male adapters for the brass bypass valve), and securely tighten them to the yoke or

bypass valve. Again, doing this before you re-attach them back onto the rear of the

valve body assembly.

Installation

Содержание PTSF-2510-10

Страница 1: ...For Model PTSF 2510 10 PTSF 2510 13 Owners Manual Installation Instructions...

Страница 16: ...Timer Assembly Tech Support 1 888 989 7873 PURE WATER TREATMENT INC Page 16...

Страница 18: ...Control Valve Drive Assembly Tech Support 1 888 989 7873 PURE WATER TREATMENT INC Page 18...

Страница 20: ...Control Valve Base Assembly Tech Support 1 888 989 7873 PURE WATER TREATMENT INC Page 20...