- 10 -

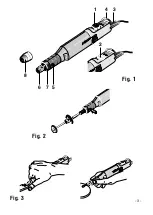

Description of machine

The PROXXON drilling and milling machine

MICROMOT 50 (E/EF) is the ideal tool for

precise drilling, milling, grinding, polishing,

brushing, rust removal, engraving, chasing

and cutting.

For hobby electronics, model making,

precision mechanics, jewellery shops,

opticians, arts, tool and mould making.

For marking tools and cameras.

It can be used on steel, non-ferrous metals,

glass, wood, minerals and ceramics.

The drill spindle is supported in a precision

ball bearing which eliminates any play.

Excellent handling because of the pen-type

grip.

The machine is reliably driven by a high

torque motor. Type 50/E-EF is fitted with an

electronic speed regulator.

Technical data

Length:

approx. 220 mm

Weight:

approx. 230 g

Spindle collar:

ø 20 mm

Motor:

Speed (50):

20 000 rpm

Speed (50/E):

5000 to 20 000 rpm

Voltage:

12 to 18 V

Power consumption:

approx. 40 W

Noise level:

≤

70 dB (A)

Please do not dispo

off the machine!

Accessories:

Drill chuck for Micromot machines

Power unit NG 2 (S/E) or NG 5 (E)

Drill stand MBS 140

Universal holder UH 34

Operation

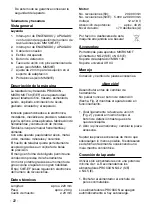

Clamping, changing tools

Attention!

Disconnect mains plug before changing tools.

Never press the locking knob (arrow Fig. 2)

while the machine is running.

1. Turn the spigot nut 1 (Fig. 2) gently while

pressing the locking knob until it engages.

2. Open the clamping jaw and change the tool.

Clamp all tools as short as possible. Shafts,

which protrude too far will bend easily

causing the machine to vibrate.

Power supply

Use only power units with a minimum power

output of 1 A. We re commend use of the

PROXXON power units NG 2 (S/E) or NG 5 (E).

1. Push the non-reversible plug into the

power unit.

If overloaded, the PROXXON power unit will

switch off automatically. Disconnect mains

plug and let the power unit cool down for a

few minutes.

Working with the machine

Always wear goggles. Do not use any broken

grinding discs or bent shafts.

2. Switch the machine on 1 or 4 (Fig. 1) and

set the correct speed (50/E only) with the

button 1.

Note:

Pressing hard does not achieve good results

when grinding. Use the correct speed and

maintain it.

Small tools pins

= high speed

Big tools pins

= low speed

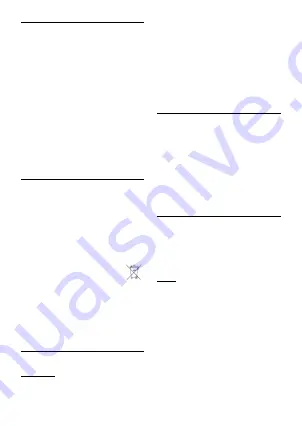

3. Fig. 3 shows two typical methods for

holding MICROMOT 50. When working,

ensure that the tool is held firmly in order

to guide the rotating application tool in a

controlled manner without thereby blocking

the ventillation slots.

Содержание MICROMOT 50 EF

Страница 3: ... 3 4 CXC X CXC CXC XC CXC CXC X 4 CXC X CXC CXC XC CXC CXC X Fig 1 Fig 2 Fig 3 ...

Страница 53: ... 53 ...