AAM

−

136

Revised June 5, 2012

29

“NICKS” AT HOLE EDGES

RUSTY APPEARANCE OR

VISIBLE DISCOLORATION

Fig. 41 Orifice Plate Damage.

KNIFE INSERT REMOVAL (Fig. 42 )

Insert point of Insert Remover Tool into slot at

locating pin end of insert. Gently pry upward and

lift worn insert out of slot. Repeat for all inserts.

Discard worn inserts.

KNIFEHOLDER

INSERT REMOVER TOOL

INSERT

Fig. 42 Knife Insert Removal.

KNIFE INSERT INSTALLATION (Fig. 43 )

Line up the new insert over locating pin and push

gently down into insert slot. Tap new inserts in

place using a soft hammer. Replace inserts when

they have worn down

1/8”

(3mm) or more.

KNIFEHOLDER

INSERT

SOFT

HAMMER

Fig. 43 Knife Insert Installation.

CENTERING PIN AND BUSHING (Fig. 44 )

Pins and bushings are not re

−

buildable and should

be replaced as often as is necessary. If total

clearance between pin and bushing bore is

1/32”

(.79mm) or more, replace both.

WEAR AREA

BUSHING

(BCA ONLY)

CENTERING PIN

WEAR AREA

Fig. 44 Centering Pin & Bushing.

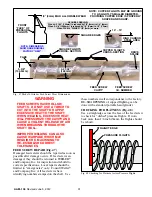

KNIFE TENSION SPRING (Fig. 45 )

Knife tension springs may occasionally weaken,

break or get lost. Keep a good supply on hand.

1

−

3/8”

(35mm)

Fig. 45 Knife Tension Spring.