AAM

−

136

Revised June 5, 2012

27

TEMPERATURE RISE

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

Plate holes too small, RPM too fast, product

over

−

worked or mixed. Any of the previous

causes could apply. Normally,

LOW

OUTPUT

is associated.

Re

−

read solutions to

LOW OUTPUT

.

Temperature rise can sometimes be reduced

by slowing RPM, a bigger hole plate or

correct feed screw.

NO OUTPUT

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

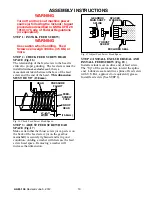

Grinder malfunction due to:

a. Loose Ring.

b. Missing or broken spring.

c. Improper feed screw/head space.

d. Plate plugged.

e. Circuit breaker “tripped”.

f. Drive belts slipping.

Grinder malfunction remedies:

a. Tighten Ring.

b. Replace spring.

c. Check and adjust spacing.

d. Disassemble and clean behind plate.

e. Reset breaker. Check amp draw and

size of breakers. Check electrical

wiring.

f. Tighten belts.

ERRATIC OUTPUT

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

Dis

−

similar products cause erratic output.

Check grinder application with WEILER

r

and Company, Inc.

2.

“Fatting Out” can cause momentary

blockage, which frees itself after a certain

amount of build

−

up. It is usually caused by

over

−

mixing or over

−

working the product.

Check length of product pre

−

mix time and/or

method of mix. Consult WEILER

r

and

Company, Inc.

PREMATURE WEAR

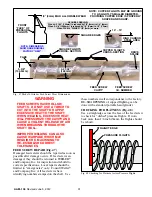

IMPORTANT: FAILURE to replace the feed screw centering pin and/or plate bushing will

allow the feed screw to wear prematurely. Excessive wear will also affect cutting action

of the knife and plate.