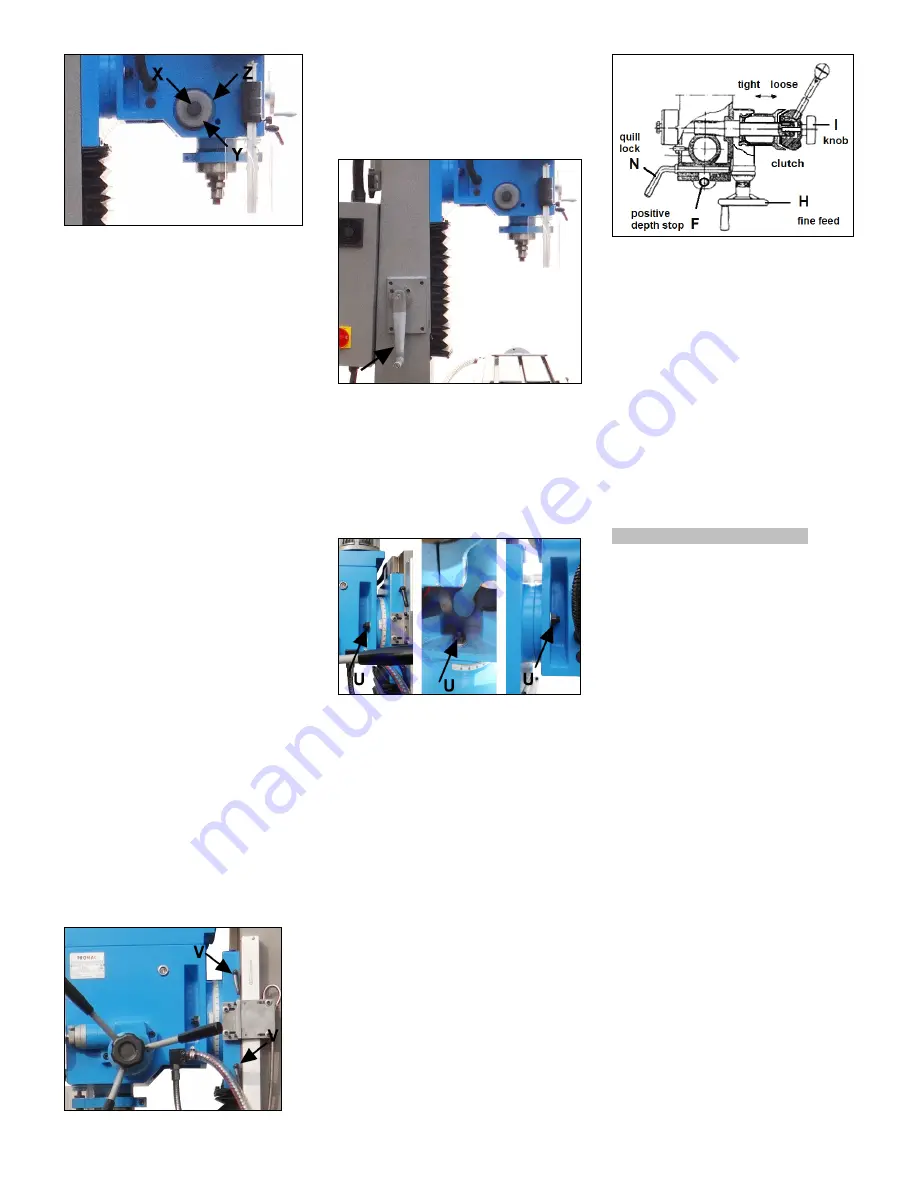

Fig 5

Firmly hold the spring cover (Y).

Pull out the cover and rotate until the pin

(Z) on the return spring plate engages

the next notch in the coil spring cover.

Turn the cover clockwise to decrease

tension and counter-clockwise to

increase tension.

Tighten knob (X).

7.6 Before Operation

Prepare oil gun with coolant or cutting

oil.

In order to keep the accurate precision,

the table must be free form dust and oil

deposites.

Check to see that the tools are correctly

set and the workpiece is set firmly.

Be sure the speed is not set to fast.

Be sure everthing is ready before use

7.7 After Operation

Turn off the electric switch.

Turn down the tools.

Clean the machine and coat it with

lubricant.

Cover the machine with cloth to keep

out the dust.

7.8 Adjustment of Head

To raise and lower the head, loosen the

two nuts (V, Fig 6) located on the right

side of the Z-slide.

Fig 6

Use the crank (Fig 7) to raise and lower

the head.

When the desired height is reached

tighten the 2 nuts to avoid vibration.

Fig 7

The head may be rotated 360º around

the column.

Loosen the 2 nuts (V, Fig 6).

Adjust the head, then well tighten the

nuts to avoid movement under

machining loads.

Fig 8

The head may be tilted left/right.

Loosen 3 nuts (U, Fig 8).

Tilt the head to the degrees you wish on

the scale, then well tighten the 3 nuts to

avoid vibration.

7.9 Preparing for Drilling.

Loosen the quill lock (N, Fig 4, Fig 9).

Loosen the knob (I) to make loose the

taper clutch of worm gear, to disengage

the fine feed (H).

Set the positive depth stop (F) to the

desired drilling depth.

Fig 9

7.10 Preparing for Milling

Adjust the positive depth stop (F, Fig 9)

to highest point position.

Turn tight of the knob (I) to engage the

taper clutch, to engage the fine feed (H).

Turn the fine feed hand wheel (H) to

adjust the desired machining height.

Tighten the quill lock (N) to avoid

vibration.

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair

work may only be carried out after

the machine is protected against

accidental starting.

Push the emergency stop button and

disconnect from the power source!

Clean the machine regularly.

Defective safety devices must be

replaced immediately.

Repair and maintenance work on the

electrical system may only be carried

out by a qualified electrician.

8.1 Weekly Lubrication:

Weekly apply oil:

DIN 51502 CG ISO VG68

(e.g. BP Maccurat 68, Castrol Magna BD

68, Mobil Vectra 2)

- X-axis lead screw

Apply oil on entire length.

- Y-axis lead screw

Move the table forward and remove the

way cover for access.

Apply oil on entire length.

- Z-axis lead screw

Move the head up and remove the way

cover for access.

Apply oil on entire length.

Содержание JMDT-804516-DRO

Страница 9: ...JMDT 804516 DRO Headstock Assembly 1...

Страница 13: ...JMDT 804516 DRO BASE PARTS 2...