V160K

• Installation must be carried out in accordance with the

circuit or piping diagram.

• Always cover or cap all motor case drain and high pres-

sure hydraulic lines during the installation of a new or

replacement motor.

• Always ensure that all connections to the motor or re-

placement motor are capped or covered during the initial

installation.

• Connect and tighten each hydraulic line one at a time

removing caps or covers just before each connection is

made.

• Additional care must be taken to vent entrapped air from

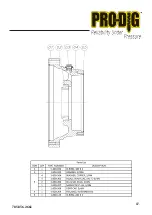

the motor rear head. If mounted as shown below, connect

the “vent line” to the reservoir.

Please note that all PRO-

DIG

®

V Series drives are fitted with a vent valve and

thus no extra precautions are required during installa-

tion

.

VENTING CASE DRAIN

• Positive venting is essential for the correct operation of the

hydraulic system.

• All case drain lines must be mounted continuously rising

towards the reservoir. This allows any entrapped air to

escape freely from the motor housing.

• The PRO-DIG

®

Auger Drive is supplied with a case drain

hose already installed. This hose must be directly connect-

ed to the reservoir and should be below the oil level in the

reservoir and should be below the oil level in the reservoir,

as illustrated below.

• The case drain line pressure is not permitted to exceed 22

PSI.

PIPING

• Pipe work should be seamless drawn precision steel tube

or hoses of suitable pressure rating.

• During installation, attention should be paid to cleanliness.

The pipes must be de burred, washed and blown through.

• Scaled or rusted pipes must be scoured and then neutral-

ized. Hoses must be brushed and flushed through when

contaminated.

IMPORTANT: The cleanliness of the circuit

before

commis-

sioning has a crucial influence on the operation and life

expectancy of the hydraulic components.

OPERATING PROCEDURES

785.856.2661

WWW.PRO-DIG-USA.COM

7.

Содержание V160K

Страница 14: ...V160K WWW PRO DIG USA COM 14 PAGE 15 PAGE 16 PAGE 17 PAGE 18 PAGE 21 PAGE 22 PAGE 23 PAGE 24 PAGE 19 PAGE 20 ...

Страница 15: ...785 856 2661 15 ...

Страница 16: ...V160K WWW PRO DIG USA COM 16 ...

Страница 17: ...785 856 2661 17 ...

Страница 18: ...V160K WWW PRO DIG USA COM 18 ...

Страница 19: ...785 856 2661 19 ...

Страница 20: ...V160K WWW PRO DIG USA COM 20 ...

Страница 21: ...785 856 2661 21 ...

Страница 22: ...V160K WWW PRO DIG USA COM 22 ...

Страница 23: ...785 856 2661 23 ...

Страница 24: ...V160K WWW PRO DIG USA COM 24 ...

Страница 25: ...NOTES 785 856 2661 25 ...

Страница 26: ...PROUD MEMBER OF 1604 ROSEPORT RD ELWOOD KS 66024 785 856 2661 WWW PRO DIG USA COM ...