3

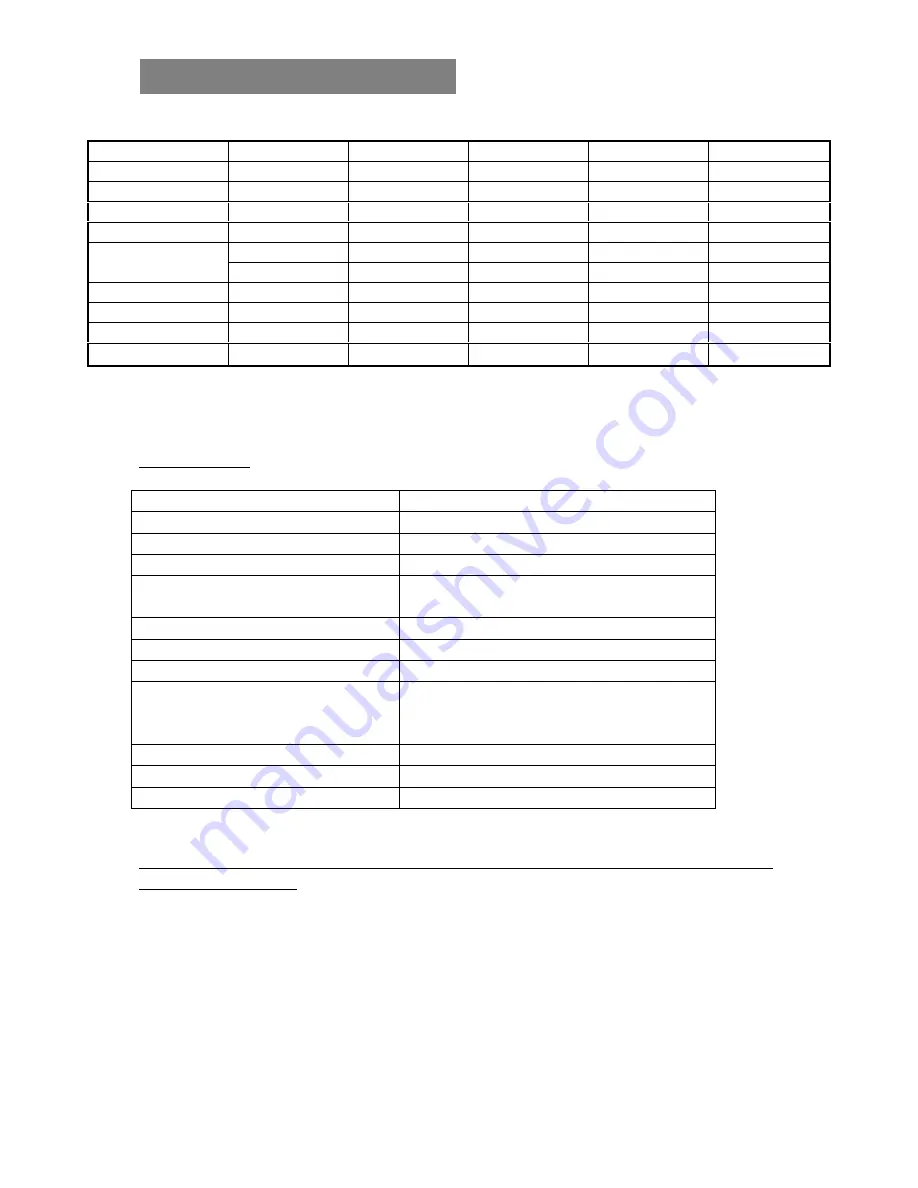

Model

Ecovapor/1-2, 5 Ecovapor/1-4

Ecovapor/2-4

Ecovapor/2-4

Ecovapor/2-6

Heating capacity

2,5KW

4KW

4KW

4KW

6KW

Steam outlets

1

1

2

2

2

Steam capacity

3,25kg/h

5,2kg/h

5,2kg/h

5,2kg/h

7,9kg/h

Power supply

230V-1ph-50Hz

230V-1ph-50Hz

230V-1ph-50Hz

400V-3ph-50Hz

400V-3ph-50Hz

Steam pressure

3,5 bar

3,5 bar

3,5bar

3,5bar

3,5bar

4,5 bar Special

4,5 bar Special

4,5 bar Special

4,5 bar Special

4,5 bar Special

Packing Dim.

54X59X99cm

54X59X99cm

54X59X99cm

54X59X99cm

54X59X99cm

Net Weight

53kg

53kg

53kg

53kg

53kg

Gross Weight

58kg

58kg

58kg

58kg

58kg

Code

103-06-004

103-06-003

103-06-001

103-06-002

103-06-007

For all 5 models

Normal working pressure

3,5 bars

Max working pressure

4,2 bars

Admissible design pressure

6,2 bars

Steam temperature 3,5bars

149

o

C

Electric connections

Neutral wire and earth wire separate

according to VDE Regulations

Boiler capacity

8,5lt

Max. boiler’s water capacity

4lt

Min. boiler’s water capacity

3,5lt

Wiring according to European

Specifications

Blue-Neutral wire

Green/yellow-earth wire

Brown or black-phase

Feeding-water tank

25lt

Condensate tank

10lt

Heating-up time

Ca 15-20 minutes

CAUTION! PLEASE READ CAREFULLY THE INSTRUCTION MANUAL BEFORE INSTALLING THE

STEAM GENERATOR!!!

All specifications have been made to the best of our knowledge.

Specifications may be subject to change without any prior notice.

Models - Technical specifications