8

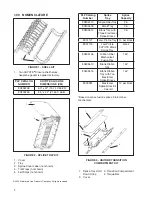

FIGURE 15A - ATTACH "L" BRACKET–

FRONTAL VIEW

FIGURE 15B - ATTACH "L" BRACKET–SIDE VIEW

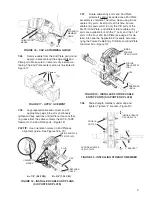

7.02

Remove the protective vinyl tape applied to

LOCK-TAPE Sealant in Paragraph 4.08.

7.03

Place the cable into the End Plate as close to

the assembly location as possible. Mark it

1/4-1/2" (.64-1.27 cm) from the outside surface of the

End Plate. Apply vinyl tape over the remaining LOCK-

TAPE Sealant.

Do not apply vinyl tape in the seal

area.

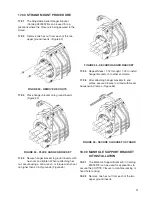

7.04

Use the strength member cap on the "L"

bracket as a guide for trimming the strength

member. (Figure 16)

PLP TIP:

A long "L" bracket is available (Catalog

#80805431) for bonded loose buffer tube cable

with a dielectric central strength member.

FIGURE 14B - LONG "L" BRACKET

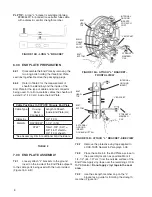

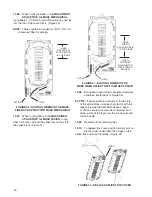

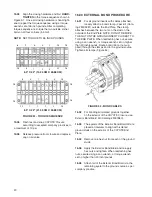

6.00 END PLATE PREPARATION

6.01

Disassemble the End Plate by removing the

two long bolts holding the three End Plate

sections together. Remove the packaging plugs.

6.02

Refer to Table 2 for the measurement of

sheath to extend beyond the inside of the

End Plate for the type of cable and bond connector

being used. For all non-metallic cables the sheath will

extend 3/4" (1.90 cm) inside the End Plate.

Cable Positions In COYOTE Closure End Plate

Cable Type

If using

Bond

Connectors

Length of Sheath

Inside End Plate (cm)

Dielectric

3/4" (1.90)

Metallic

RAYCHEM* 1-1/4" (3.18)

AT&T*

Total 1-3/8" (3.47) =

5/8" (1.57)

3/4" (1.90) sheath

*See Accessory Kits for additional bond hardware

TABLE 2

7.00 END PLATE ASSEMBLY

7.01

Loosely attach "L" brackets to the ground

insert on the inside of the End Plate adjacent

to the cable ports being used with the nut provided.

(Figure 15 A & B)

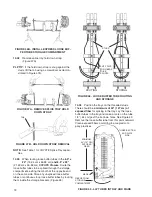

INTERNAL

GROUND

INSERT

BOLT

HEAD-

TOP

EXTERNAL

GROUND

INSERT--

DOUBLE-NUTTED

"L" BRACKET

BOLT-

BOTTOM

STRENGTH

MEMBER

CAP

"L" BRACKET

BOLT

HEAD-

TOP

BOLT-

BOTTOM

INTERNAL

GROUND

INSERTS

FOR EACH

PORT

STRENGTH

MEMBER

CAP

MAIN

CABLE

PORT

ENTRY