6

BI-DIRECTIONAL TOOL TURRETS

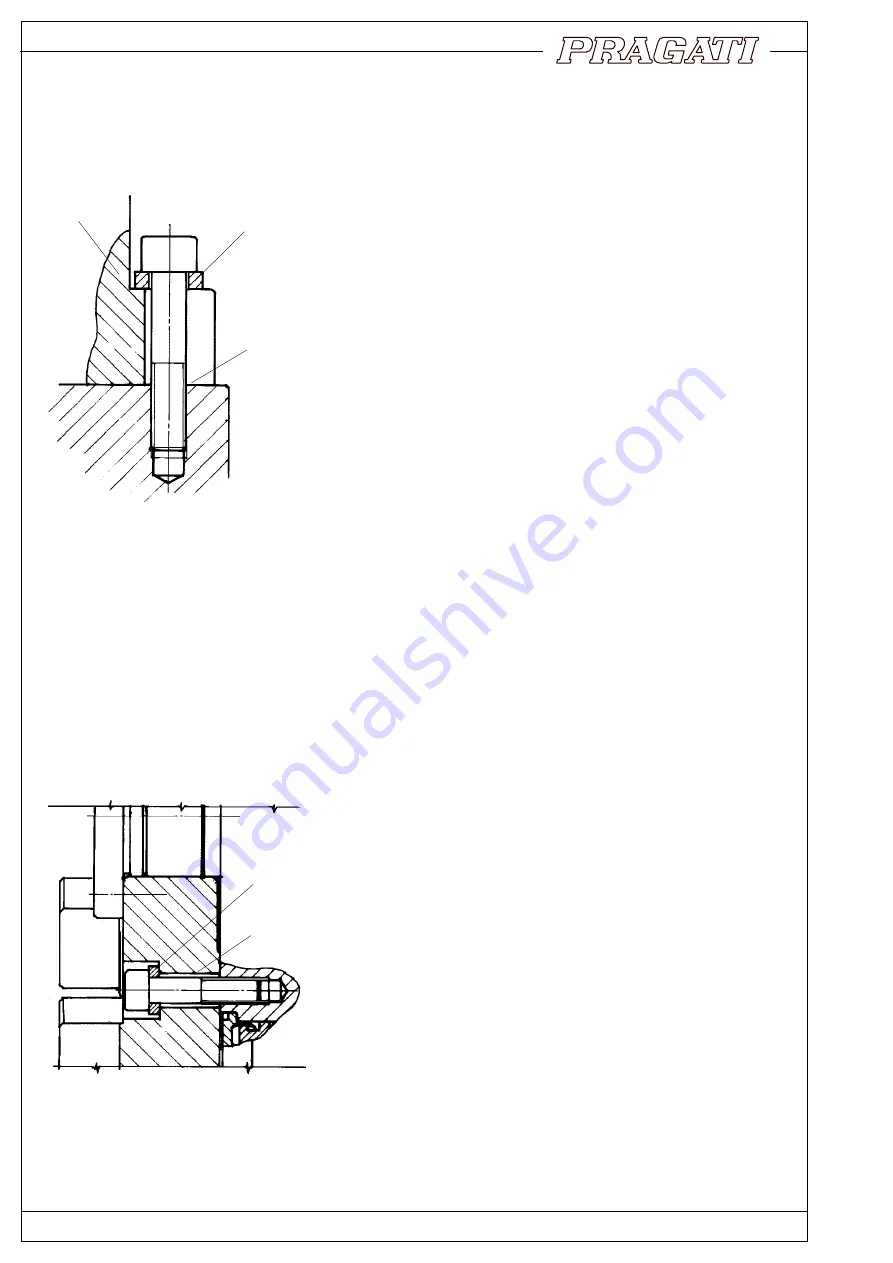

2. Fitment on the machine :

Seating surface of the machine should be flat to ensure proper

contact with the turret base. Machine surface should be either

scraped or surface-ground.

Turret should be aligned by dialing surface of the indexing

flange. Clamping bolts should be tightened after aligning the

seating surface, square to the lathe axis.

Clamping bolts should use machine washers of extra thickness

(min.5 mm) to ensure proper clamping.

Dowel Pins are not recommended for ensuring the alignment

of turret. It is preferable to allow the turret to slip in the event

of an accidental shock or overload. This slipping absorbs

some of the energy of the shock and reduces the possible

damage. Turret can again be brought back to alignment by

dialing a reference surface on the tool disc.

There is one more reason for avoiding the dowel pin. Acci-

dental collisions are not un-common in the field of CNC lathes.

In the event of a collision, dowel pins can get sheared or

damaged. It is a difficult task to remove such dowel pins, and

to fit new ones. New dowels may involve enlarging the

damaged hole by drilling and reaming. This is difficult to do at

the customer's place. This is a difficult operation to be done on site, and is most likely to be less than perfect.

On the other hand, it is perfectly possible to use the turret and tool disc without the use of dowels. The friction

joint can easily take up normal cutting loads, including occasional over loads.

Pragati turrets, therefore, do not have a provision of dowelling the body to the base.

TOOL

DISK

3. Fitment of Tool Disc on Turret Flange :

Tool disc is to be fitted on the indexing flange with the help of

clamping bolts, and machine washers. Disc should be angularly

adjusted within the clearance of the bolt holes, to get the correct

centre height of the tool. It should then be firmly clamped by

tightening the bolts. Dowel pins for ensuring the position are not

recommended for the reasons explained earlier.

However, dowel pin can be used for the purpose of alignment, but

it is recommended to remove the pin after clamping the tool disc

in position. There is a provision of soft areas on the indexing flange

to facilitate drilling and reaming for dowel pins.

Bolt holes in the tool disc should be of extra large size to allow for

angular adjustment. Extra thick machine washers should be used

to ensure proper clamping.

TURRET

BODY

FLAT

SEATING

SURFACE

(SCRAPED OR

GROUND)

EXTRA THICK

WASHERS

OVERSIZE

BOLT HOLE

EXTRA

THICK

WASHERS

FIG 3.1

FIG 2.1

Содержание BTP-100

Страница 16: ...FIG 15 3 MAIN SPINDLE ASSEMBLY BI DIRECTIONAL TOOL TURRETS 17...

Страница 17: ...18 BI DIRECTIONAL TOOL TURRETS FIG 15 4B INDEXING DRIVE BTP 125 BTP 100 FIG 15 4A INDEXING DRIVE BTP 80 BTP 63...

Страница 18: ...BI DIRECTIONAL TOOL TURRETS 19 FIG 15 6 MOTOR ASSEMBLY FIG 15 5 COOLANT VALVE ASSEMBLY...