2

3

Function

The load hook is raised or lowered by pulling on the hand chain.

The load will remain where it is when the hand chain is released because of the effective reaction brake.

Max. hand force need to be respected to avoid overloading of the hoist.

The Over Load Protection (OLP) versions are additionally equipped with an overload protection device that will limit the force that can be applied

using the hand chain.

If the OLP device is activated the hand chain will rotate but the hoist will not continue to lift, only lowering is possible.

The overload protection device is adjusted in the factory to approx. 1,3 x WLL and the device normally don’t need to be adjusted.

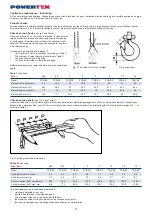

Suspension of chain block

Suspend the block from an eye, shackle, girder trolley etc. with sufficient load capacity. With the chain tightened, both hooks must be vertically

aligned.

NB!

No bending stresses may be applied to block, hooks or load chain.

Raising/lowering

Only use straps and slings of sufficient load capacity. Check that the load is not anchored to the floor/ground or is otherwise fixed before making

the lift. Ensure that the load chain hangs vertically and has no kinks. The hand chain must also be in good condition and easily accessible. The

load is raised or lowered by pulling the hand chain in either direction.

Warning:

Do not overload the brake by prolonged lowering. It may cause brake function to fail.

Warning:

•

Only hand power from a single person is permitted on the hand chain. If the chain feels too heavy, use a bigger chain block or reduce the load.

•

Make sure no-one stands beneath a hanging load.

•

Do not step onto a hanging load.

•

Do not raise or lower so far that the load hook hits the block housing.

•

The chain block must not be used for pulling loads.

•

The block must not be subjected to dynamic stresses, for example where a load connected to the block is launched from a height.

•

Do not leave a block with a suspended load unattended.

Attachment of loads

Check the equipment before use. Improper attachment of loads can be highly dangerous (see Figs. 2 a – 2 e).

Fig 2 a

The sling is applying

load to the hook tip

Fig 2 b

Excessive top angle

on sling!

α max. 60°

Fig 2 c

Hook latch

obstructed

Fig 2 d

Hook tip

subject to additional

bending stress

Fig 2 e

Load chain must not

be used as a sling

Multiple lifting

Multiple lifting entails special risks. This is is when two or perhaps more hoists are used simultaneously for the same load. Danger to persons and

material damage can arise due to dynamic stresses and uneven load distribution causing individual hoists to become overloaded. A competent

person with experience in multiple lifting must therefore supervise this type of lifting tasks.

The total weight of the target object and its load distribution must be known or calculated.

For a variety of reasons, the centre of gravity can be difficult to determine, and thus so will the distribution of the load each chain hoist must bear.

In cases where heavy, bulky loads must be handled and it is not possible to estimate all factors correctly, the working load limit (WLL) of each

chain hoist must be reduced by at least 25%.

Daily checks

After every working day on which the chain block has been used, the following should be checked:

•

Is the chain block deformed or otherwise damaged? Are any parts missing?

•

Is any deformation or other damage visible on the suspension device (eye, shackle, bolt, trolley etc.)?

•

Are the hooks intact or have any hooks opened? Are the hook latches correct and functional?

•

Wipe down the chain block and oil the load chain as required.

•

The load chain must be undamaged, i.e. no signs of wear and no deformed or otherwise damaged links.

•

The load chain must not be kinked or twisted. With two-fall or multi-fall chain blocks there is a risk of the chain twisting if the bottom hook

assembly ends up looped through the chain sling – usually during refitting or moving the chain block between work stations. See Fig 3.

•

The hand chain must also be in good condition.

•

The brake function must be intact.

In the event of faults or failures, the block must be repaired and carefully checked by a specialist before reuse.