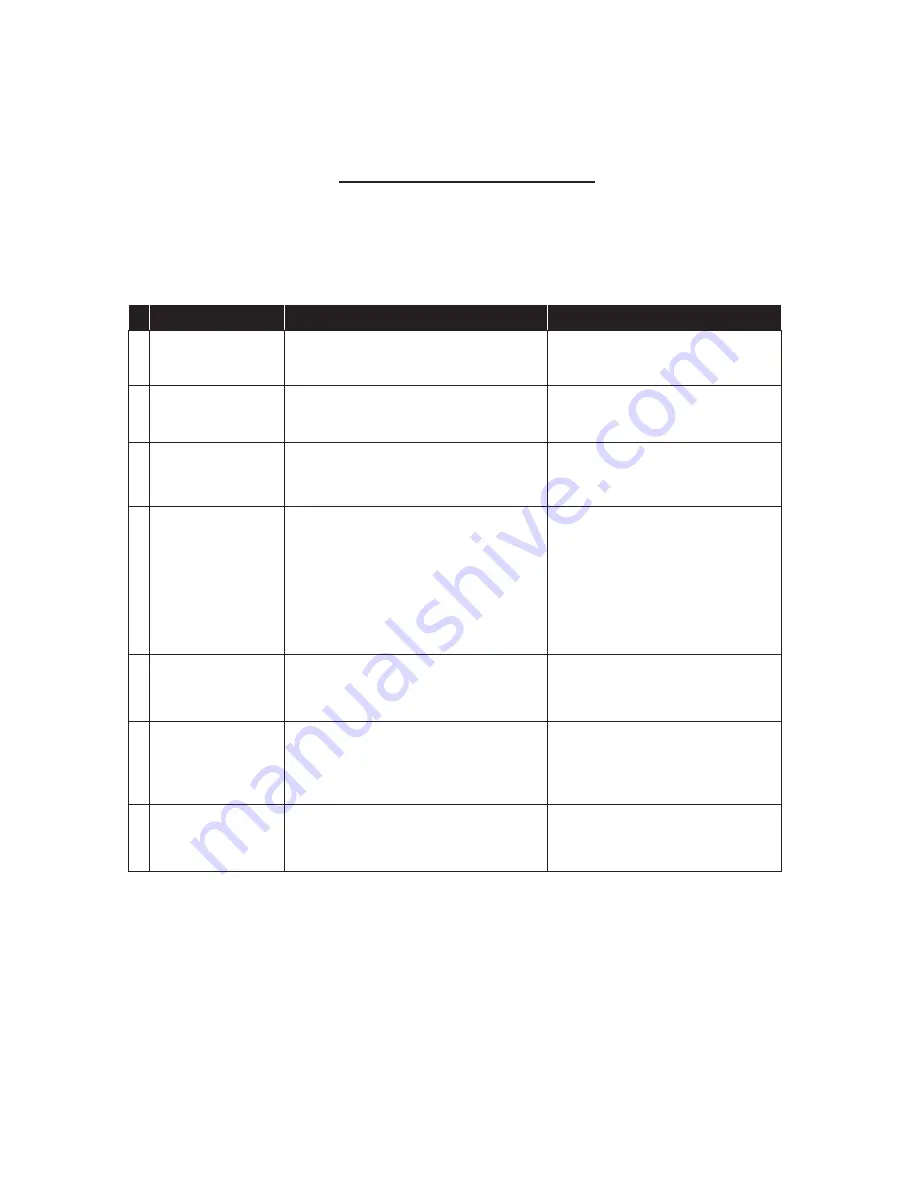

PROBLEM

POSSIBLE CAUSE

SOLUTION

1

Air leaking at

Trigger valve area

1. Damaged O-rings in trigger valve housing

1. Replace O-rings and check the

operation of safety yoke mechanism

2

Air leaking between

housing and nose

1. Loose screws in housing

1. Tighten screws

3

Air leaking between

housing and cap

assembly

1. Loose screws

2. Damaged seal.

1. Tighten screws.

2. Replace seal.

4

Tool skips driving

fastner

1. Worn bumper.

2. Dirt in nose.

3. Dirt or damage prevents fasteners from

moving freely in magazine.

4. Inadequate air fl ow.

5. Worn O-ring on piston or lack of lubrication.

6 Damaged O-rings on trigger valve.

7. Air leaks.

8. Air leakage due to worn cap seal.

1. Replace bumper

2. Clean nose.

3. Clean magazine and inspect and repair

damage.

4. Check fi tting, hose and air pressure.

5. Replace O-rings and lubrication.

6. Replace O-rings.

7. Tighten screws and fi ttings.

8. Replace seal.

5

Weak drive

1. Tool not lubricated.

2. Broken spring in cap assembly.

3. Exhaust port in cap is blocked.

1. Lubrication.

2. Replace spring.

3.Clean or replace damaged internal

parts.

6

Tool jams

1. Worn or damaged nose.

2. Damaged driver.

3. Incorrect size of fastners.

4. Bent fasteners.

5. Magazine or nose screws are loose.

1. Replace nose.

2. Replace driver.

3. Use recommended fasteners.

4. Replace with new fasteners.

5. Tighten screws.

7

Tool does not fi re

1. Fasteners jammed in magazine or discharge

area.

2. Piston shaft is damaged.

3. Air pressure too low.

1. Inspect and clean magazine.

2. Replace piston shaft.

3. Check/increase air pressure.

Here are some common issues that may occur during use.

If the nailer is not working as it should, stop using the tool immediately and resolve the

issue before continuing.

9

TROUBLE SHOOTING CHART

Содержание 1890U PowerStapler

Страница 8: ...8...

Страница 11: ...11 MODEL 1890U SCHEMATIC 14A 14 10 16 18 55A...