25

13.0

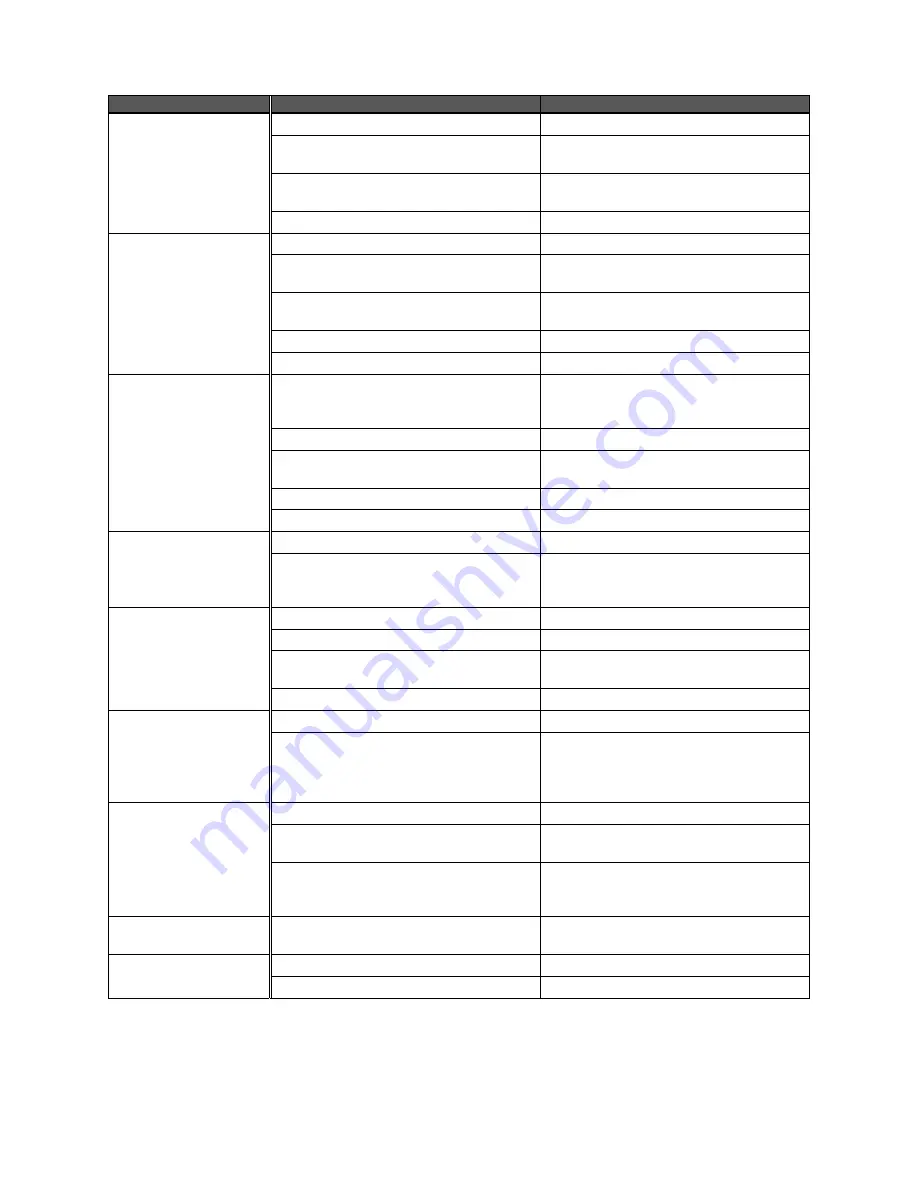

Troubleshooting PM2014 Lathe

Trouble

Probable Cause

Remedy

Motor fails to develop

full power.

Power supply line overloaded.

Correct overload condition.

Undersized wires in power supply

system.

Increase supply wire size.

Inverter fault (display reads “Err”).

Contact Powermatic Technical Service,

800-274-6846.

Motor fault.

Have motor inspected and replaced.

Motor or spindle stalls

or will not start.

Excessive cut.

Reduce depth of cut.

Improper belt adjustment, or worn or

broken belt.

Adjust or replace belt as needed.

Improper cooling of motor.

Blow out sawdust from motor housing

fan.

Worn spindle bearing(s).

Replace bearing(s).

Motor fault.

Have motor inspected and replaced.

Excessive vibration.

Workpiece warped, out of round, has

major flaw, or was improperly prepared

for turning.

Correct problem by planing or sawing

workpiece, or discard entirely and use

new workpiece.

Motor mount lock handle is loose.

Tighten lock handle.

Lathe on uneven surface.

Mount lathe to level, flat surface. Adjust

levelers if using stand.

Worn spindle bearing(s).

Replace bearing(s).

Improper belt adjustment, or worn belt.

Adjust or replace belt.

Lathe runs at one

speed only.

Potentiometer (speed dial) fault.

Replace potentiometer.

Electronic AC inverter is not

programmed properly, or is defective, or

there is loose wiring.

Contact Powermatic Technical Service

to help identify problem; 800-274-6846

Tools tend to grab or

dig in.

Dull tools.

Keep tools sharp.

Tool support set too low.

Reposition tool support height.

Tool support set too far from workpiece. Reposition tool support closer to

workpiece.

Improper tool being used.

Use correct tool for operation.

Headstock moves

when applying

pressure with

Tailstock.

Headstock not locked to bed.

Tighten headstock locking handle.

Excessive pressure being applied by

tailstock (more than 500 lbs. of force).

Slide headstock to left end, then apply

pressure to workpiece with tailstock.

Apply

only

sufficient force with tailstock

to hold workpiece securely in place.

Tailstock moves when

applying pressure.

Locking handle not tightened.

Tighten locking handle.

Cam lock nut needs adjusting.

Turn tailstock over and tighten cam lock

nut.

Lathe bed and tailstock mating surfaces

are greasy or oily.

Remove tailstock and clean surfaces

with a cleaner/degreaser. Re-apply light

coat of oil to bed surface.

LED display does not

work.

Digital sensor out of position or

damaged.

Open belt access door and inspect

sensor. Reposition or replace.

Spindle has slight

wobble (runout)

Bearings are worn or damaged.

Replace bearings.

Spindle is damaged.

Replace spindle.

Table 2

Содержание PM2014

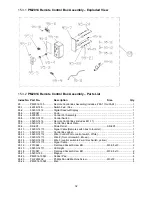

Страница 27: ...27 15 1 1 PM2014 Headstock Assembly Exploded View ...

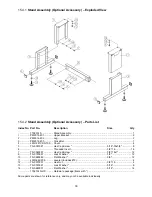

Страница 30: ...30 15 2 1 PM2014 Bed Toolrest and Tailstock Assemblies Exploded View ...

Страница 35: ...35 16 0 Electrical connections PM2014 Lathe cont next page ...

Страница 36: ...36 cont ...

Страница 38: ...38 This page intentionally left blank ...

Страница 39: ...39 This page intentionally left blank ...

Страница 40: ...40 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com ...