4

!

SAFETY RULES

As with all machines, there is a certain amount of hazard involved with the use of this sander. Use the machine with

the respect and caution demanded where safety precautions are concerned. When normal safety precautions are

overlooked or ignored, personal injury to the operator can result.

Read, understand and follow the safety and operating instructions found in this manual. Know the limitations and

hazards associated with this machine.

Electrical grounding. Make certain that the machine frame is electrically grounded and that a ground lead is

included in the incoming electrical service. In cases where a cord and plug are used, make certain that the

grounding plug connects to a suitable ground. Follow the grounding procedure indicated in the National Electrical

Code.

Power on. Before connecting power to the sander, make sure the start switch is in the "OFF" position.

Protect yourself. Protect yourself at all times when operating the wide belt sander. Avoid eye injury by wearing

approved safety shields, goggles or glasses at all times (NOTE: Common eye glasses are only impact-resistant,

they are not safety glasses). Wear protective footwear. Steel toed shoes are recommended because heavy parts

can fall off the conveyor table onto feet.

Personal protection. Before operating the machine, remove tie, rings, watch and other jewelry and roll up sleeves

above the elbows. Remove all loose outer clothing and confine long hair. Protective type footwear should be used.

Where the noise exceeds the level of exposure allowed in Section 1910.95 of the OSHA Regulations, use hearing

protective devices. Do not wear gloves.

Guards. Do not operate the sander with guards off. Keep the guards in place at all times when the machine is

running. If removed for maintenance purposes or any other reason, use extreme caution and replace the guards

upon completion of the task and before using the machine again. Injury can result from exposure to the machine's

internal moving parts.

Check damaged parts. Before continuing use of the machine, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and safely and perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that could

effect its operation. A guard or other part that is damaged should be properly repaired or replaced before machine

operation continues.

Work area. Keep the floor around the machine clean and free of scrap material, saw dust, oil and other liquids to

minimize the danger of tripping or slipping. Be sure the table is free of all scrap, foreign material and tools before

starting to cut. Make certain the work area is well lighted and that a proper exhaust system is used to minimize dust.

Powermatic recommends the use of anti-skid floor strips on the floor area where the operator normally stands and

that each machine’s work area be marked off. Provide adequate work space around the machine.

Operator position. Stand to one side of the conveyor table and make sure no one else is standing in line with the

table while feeding into the machine. The wide belt sander operates at high speed and should a part slip, it will exit

the machine at a high rate of speed and may result in injuiries to anyone standing directly in front of the infeed.

(Keep conveyor belt clean and check pin-roll adjustments.) Maintain a balanced stance and keep your body under

control at all times. Do not overreach or use excessive force to perform any machine operation.

Hand safety. Keep hands clear while feeding parts onto the conveyor table. The part will be forced down as it

begins to feed into the machine, causing a pinching action between the part and the table. Use caution! Hands

should be clear of the stock and the table to avoid pinching. Never reach into a running machine. Turn off electrical

power and stop machine before attempting to retrieve parts from within the machine. Contact with internal moving

parts can result in loss or injury to fingers, hands and arms.

Housekeeping. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap, and

cleaning rags away from the machine

Содержание 1632

Страница 15: ...15 Electricity Control Upper Adj Roller 1632 Sander ...

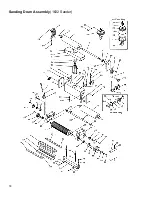

Страница 18: ...18 Sanding Drum Assembly 1632 Sander ...

Страница 21: ...21 Base Table Adjust Assembly 1632 Sander ...

Страница 24: ...24 Conveyor Belt Table 1632 Sander ...

Страница 25: ...25 Reduction Motor 1632 Sander ...

Страница 26: ...26 ELECTRICAL SCHEMATIC 1632 Sander 460V 3 Phase ...

Страница 27: ...27 ELECTRICAL SCHEMATIC 1632 Sander 230V 1 Phase 3 Phase ...

Страница 28: ...28 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60123 Phone 800 274 6848 www wmhtoolgroup com ...