10

OPERATION

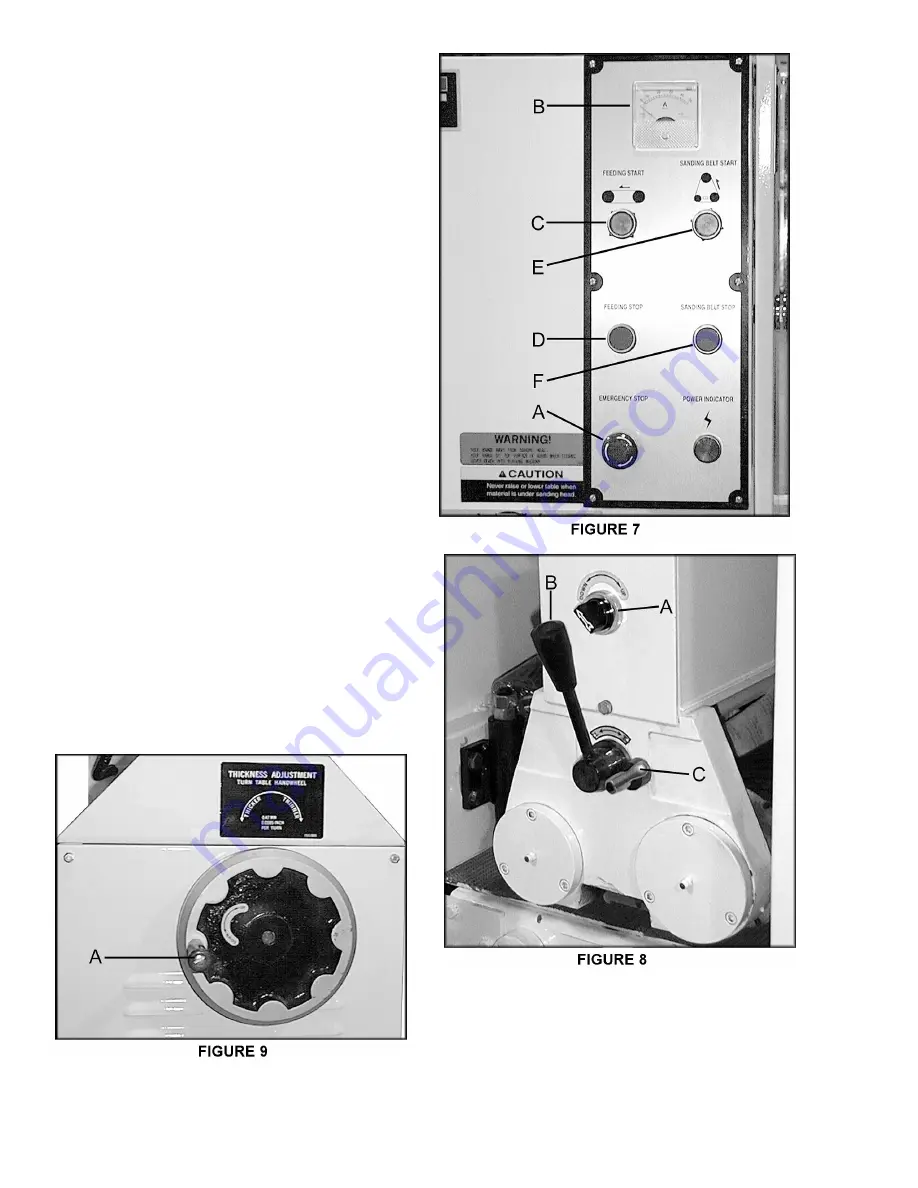

CONTROLS

(Figure 7):

Emergency stop (A) will stop the feeding belt and

sanding belt. The button must be turned clockwise

to reset sanding functions.

Amp Meter (B) displays the amperage.

Feeding Start (C) will start the feeding belt only.

Feeding Stop (D) will stop the feeding belt only.

Sanding Belt Start (E) will start the sanding belt

only.

Sanding Belt Stop (F) will stop the sanding belt

only.

NOTE: The orange bar on the front of the infeed

roller acts as a safety stop. When the bar is

pressed, the brakes are applied.

1.

Connect the air line to the sander.

2.

Adjust the pressure gauge to 75 psi.

3. Engage the upper roller by turning the knob

(A), Figure 8, to the upper position.

4.

Adjust the platen with the lever (B) and lock it

(C) in the desired position. The platen or main

rubber roller can act as the sanding contact, as

well as a combination of both.

5. Rotate the main handwheel (A), on the lower

cabinet, to raise or lower the table. See Figure

9. Refer to the scale for the desired setting.

The recommended depth of sanding is .0164"

or two revolutions of the handwheel. The table

can be locked in place by the lever at the base

of the column.

Содержание 1632

Страница 15: ...15 Electricity Control Upper Adj Roller 1632 Sander ...

Страница 18: ...18 Sanding Drum Assembly 1632 Sander ...

Страница 21: ...21 Base Table Adjust Assembly 1632 Sander ...

Страница 24: ...24 Conveyor Belt Table 1632 Sander ...

Страница 25: ...25 Reduction Motor 1632 Sander ...

Страница 26: ...26 ELECTRICAL SCHEMATIC 1632 Sander 460V 3 Phase ...

Страница 27: ...27 ELECTRICAL SCHEMATIC 1632 Sander 230V 1 Phase 3 Phase ...

Страница 28: ...28 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60123 Phone 800 274 6848 www wmhtoolgroup com ...