2

Table of Contents

Important Safety Instructions

2

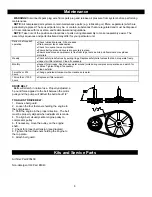

Maintenance 6

Receipt and Inspection

2

Kits & Service Parts

6

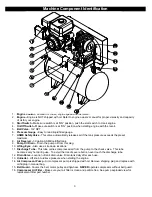

Machine Component

Identification

3

Exploded View / Component List

7-8

Assembly 4

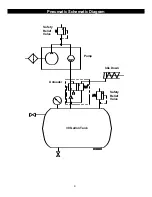

Pneumatic Schematic Diagrams

9

Operation 5

Troubleshooting 10

Limited Warranty

11

Safety

DEFINITIONS

DANGER!

WILL cause DEATH, SEVERE INJURY or substantial

property damage.

WARNING!

CAN cause DEATH, SEVERE INJURY or substantial

property damage.

CAUTION!

WILL or CAN cause MINOR INJURY or property

damage.

GENERAL SAFETY PRECAUTIONS

ALWAYS

wear eye protection when operating or

servicing compressor.

NEVER

operate where flammable or explosive liquids or

vapors such as gasoline, natural gas and solvents are

present.

NEVER

remove, paint over, or deface decals. Replace

any missing decals.

NEVER

operate with guards or shields removed,

damaged or broken.

NEVER

operate indoors. This compressor is intended

for outdoor use only. Avoid inhaling exhaust fumes, risk

of asphyxiation. Exhaust fumes are deadly.

NEVER

add fuel when the product is operating or hot.

NEVER

directly inhale compressed air.

NEVER

over-pressurize the receiver tank or similar

vessels beyond design limits.

NEVER

use a receiver tank or similar vessels that fail to

meet the design requirements of the compressor.

NEVER

drill into, weld or otherwise alter the receiver

tank or similar vessels.

NEVER

remove, adjust, bypass, change, modify or

make substitutions for safety/relief valves, unloader

valve or other pressure control related devices.

NEVER

use air tools or attachments without first

determining the maximum pressure recommended for

that equipment.

NEVER

point air nozzles or sprayers toward people or

animals.

NEVER

touch the compressor pump, engine or

discharge tubing during or shortly after operation. These

parts become hot.

BREATHING AIR PRECAUTION

Powerhorse air compressors are not designed,

intended or approved for breathing air. Compressed air

should not be used for breathing air applications unless

treated in accordance with all applicable codes and

regulations.

Receipt and Inspection

Before signing the delivery receipt, inspect for

damage and missing parts. If damage or missing parts

are apparent, make the appropriate notation on the

delivery receipt, then sign the receipt. Immediately

contact the carrier for an inspection. All material must be

held in the receiving location for the carrier’s inspection.

Delivery receipts that have been signed without a

notation of damage or missing parts are considered to

be delivered “clear.” Subsequent claims are then

considered to be concealed damage claims. Settle

damage claims directly with the transportation company.

If you discover damage after receiving the air

compressor (concealed damage), the carrier must be

notified within 15 days of receipt and an inspection must

be requested by telephone with confirmation in writing.

On concealed damage claims, the burden of

establishing that the compressor was damaged in transit

reverts back to the claimant.

Read the compressor nameplate to verify it is the

model ordered, and read the motor nameplate to verify it

is compatible with your electrical conditions. Make sure

electrical enclosures and components are appropriate.