Some people are more likely to be permanently injured

by hot water than others. These include the elderly,

children, the in

fi

rm and the physically/mentally disabled.

Table 1 (published by U.S. Government Memorandum,

1978) shows the approximate time-to-burn relationship

for normal adult skin. If anyone using hot water provided

by the water heater being installed

fi

ts into one of these

groups or if there is a local code or state law requiring a

certain water temperature at the point of use, then special

precautions must be taken.

Water

Temperature

°F

Time for 1st

Degree Burns

(Less Severe Burns)

Time for Permanent

Burns 2nd & 3rd

Degree (Most

Severe Burns)

110

(normal shower temp.)

116

(pain threshold)

116

35 minutes

45 minutes

122

1 minute

5 minutes

131

5 seconds

25 seconds

140

2 seconds

5 seconds

149

1 second

2 seconds

154

instantaneous

1 seconds

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong,

Sept. 15,1978)

Table 1.

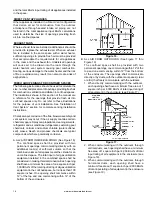

In addition to using lowest possible temperature setting

that satis

fi

es demand of application, a mixing valve should

be installed at water heater (see Figure 8 & Figure 9) or at

hot-water taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores.

Consult a Quali

fi

ed Installer or Service Agency. Follow

mixing valve manufacturer’s instructions for installation

of the valves. Before changing the factory setting on the

thermostat, read the “Operating The Temperature Control

System” section in this manual.

WATER HEATER OPERATION

Figure 10 shows the water heater’s sequence of operation

when a call for heat is initiated. The ignition control module

will attempt to light the burner three times. If the ignition

control does not detect ignition it will enter lockout mode

and

fl

ash the corresponding error code.

HEATER CONTROL

CHECKS TO ENSURE

BLOWER PRESSURE

SWITCH IS OPEN

BLOWER IS

ENERGIZED

CONTROL CHECKS

TO ENSURE PRES-

SURE SWITCH CLOSES

INDICATING BLOWER

IS OPERATING AND

THERE ARE NO

VENTING BLOCKAGES

(INLET OR OUTLET)

IGNITER IS ENERGIZED

AND MAIN GAS VALVE

IS OPENED

MAIN BURNER COMES

ON AND THE FLAME IS

SENSED BY CONTROL

MAIN BURNER CONTIN-

UES TILL THE WATER

IN THE TANK REACHES

THERMOSTAT SETTING

MAIN BURNER SHUTS

OFF. BLOWER

CONTINUES FOR A

POST PURGE TIME

HEATER

THERMOSTAT

CALLS FOR

HEAT

HEATER

REMAINS ON

STANDBY UNTIL

NEXT CALL FOR

HEAT

Figure 10.

12 www.americanwaterheater.com