3

Scroll Air Compressors

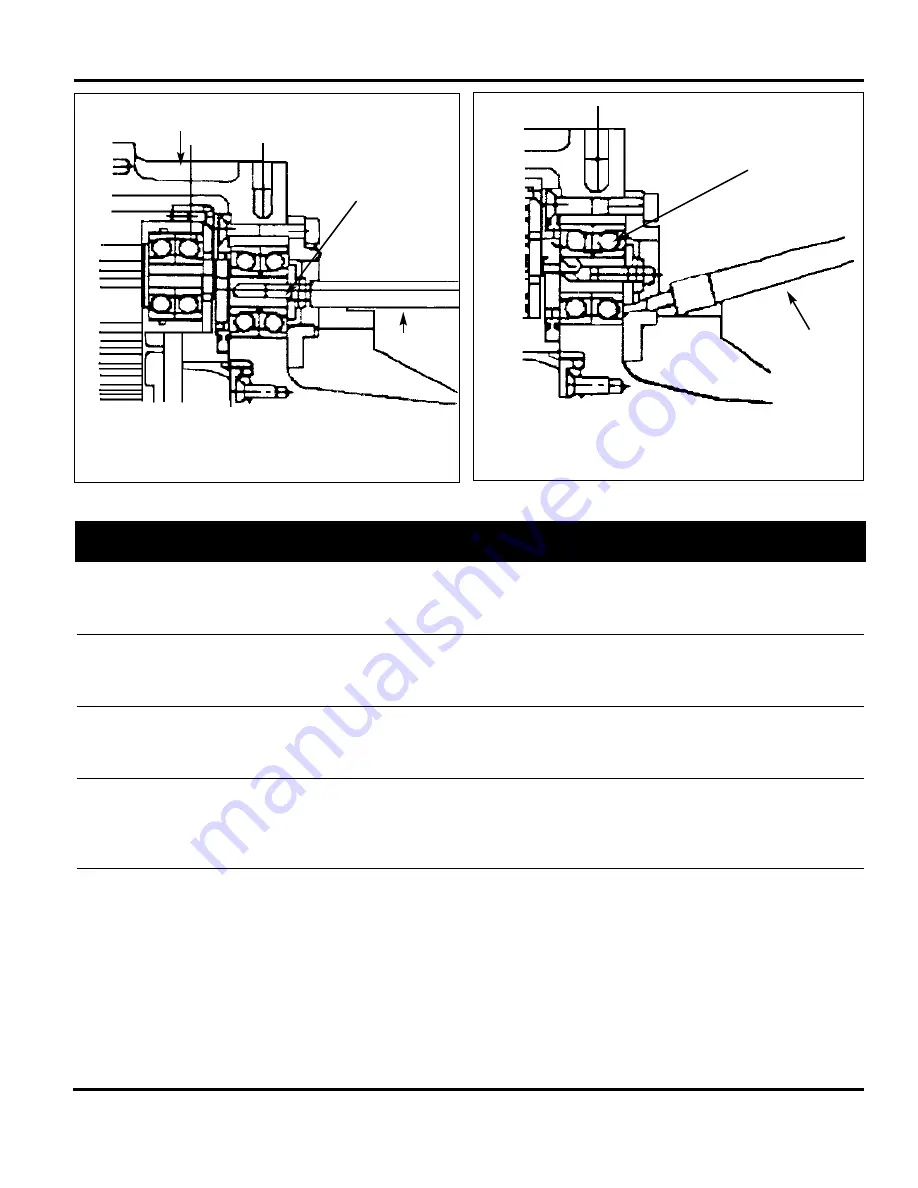

Figure 4

Figure 5

Extension

Adaptor

Needle

Adaptor

Orbit Scroll Bearings

Grease Fitting

Housing

Side Bearings

Maintenance Schedule

Operating Hours

Item

Action needed

500

2500

5000

10,000

15,000

20,000

Remarks

Tank

Drain moisture

Daily

Inlet air filter

Replace

(Every 2,500 hrs or less)

Part #IP032901AV

Blower fan

Clean

Fan Duct

Clean

Compressor Fins

Clean

(Every 2,500 hrs or less)

Bearings

Regrease

(Every 5,000 hours for 145 psig scroll)

Service Center Only

Tip seal set

Replace

(Every 5,000 hours for 145 psig scroll)

V-belt

Inspect, replace

*Note 3

Pressure Switch

Confirm operation

Magnetic starter

Inspect

Replace if contact

points deteriorated

Safety valve

Confirm operation

(Every 2,500 hrs or less)

Pressure gauge

Inspect

(Every 2,500 hrs or less)

Inspect

Replace

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse,

shorten the cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards. Proper

belt tension for 3 HP units is 7 lbs./.16” deflection; for 5 HP units, 7 lbs./.19” deflection.

4. See Compressor Pump Manuals for replacement or service procedures.