14

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

CAUTION: Do Not Change the preset tether length.

CARE AND CLEANING

CAUTION: Always use the handle to lift the pump. Never

use the power cord to lift the pump. To avoid skin burns,

unplug the pump and allow time for it to cool after periods of

extended use.

Do - When the power is disconnected, inspect the pump

suction screen and remove all debris, then plug the pump back

into the grounded (GFCI) outlet.

Do Not - Do not disassemble the motor housing. This motor

has NO repairable internal parts, and disassembly may cause

leakage or dangerous electrical wiring issues.

Do not lift up the pump by the power cord.

To clean a pump clogged with debris:

Unplug the pump from electrical power.

Unscrew the stainless screws, and remove the volute/bottom

seal plate.

Use a flathead screwdriver to hold the shaft, then turn the

impeller counterclockwise to release the impeller.

Remove debris from around the shaft and on/under the

impeller.

Reassemble the pump.

Replacement Parts:

LEVEL CONTROLS - 1/3 & 1/2Hp:

Vertical 10Ft. Cord - P/N: PFEVS10D1810P1

Vertical 20Ft. Cord - P/N: PFEVS10D1820P1

Wide Angle 10Ft. Cord - P/N: PFTFS10D1810P1

Wide Angle 20Ft. Cord - P/N: PFTFS10D1820P1

CORD SET: 1/2Hp Only.

Power Cord 10Ft. - P/N: PFL183062

Power Cord 20Ft. - P/N: PFL181061

Operation

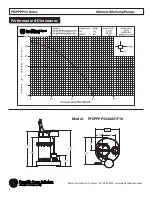

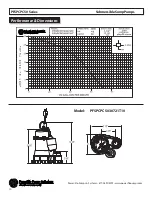

PFSPPPP33 / PFSPCPC50 Series

Submersible Sump Pumps