24

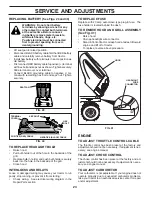

REPLACING BATTERY (

See Figs. 29 and 30

)

WARNING: Do not short battery

ter mi nals by allowing a wrench or any

other object to contact both terminals

at the same time. Before connect-

ing battery, remove metal bracelets,

wristwatch bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from ac ci -

den tal grounding.

• Lift seat pan to raised position.

•

Disconnect BLACK battery cable first then RED battery

cable and carefully remove battery from tractor.

• Install new battery with terminals in same position as

old battery.

•

First connect RED battery cable to positive (+) terminal

with hex bolt and keps nut as shown. Tighten securely.

Slide terminal cover over terminal.

• Connect BLACK grounding cable to negative (-) ter-

mi nal with remaining hex bolt and keps nut. Tighten

securely.

SERVICE AND ADJUSTMENTS

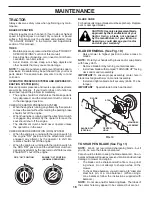

TO REPLACE HEADLIGHT BULB

• Raise

hood.

• Pull bulb holder out of the hole in the backside of the

grill.

• Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

• Close

hood.

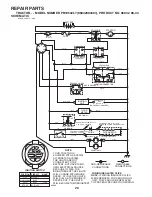

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your tractor to run

poorly, stop running, or prevent it from starting.

• Check wiring. See electrical wiring diagram in the

Repair Parts section.

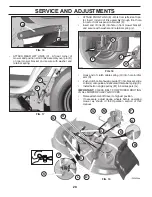

03075

HOOD

HEADLIGHT

WIRE

CONNECTOR

FIG. 31

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 31)

• Raise

hood.

• Unsnap headlight wire connector.

•

Stand in front of tractor. Grasp hood at sides, tilt toward

engine and lift off of tractor.

• To replace, reverse above procedure.

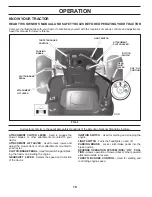

FIG. 29

FIG. 30

SEAT PAN

KEPS NUT

HEX

BOLT

POSITIVE (RED) CABLE

NEGATIVE (BLACK) CABLE

TER MI NAL

COVER

ENGINE

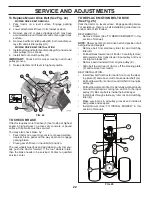

TO AD JUST THROTTLE CON TROL CABLE

The throttle control has been preset at the factory and

ad just ment should not be necessary. If adjustment is nec-

es sary, see engine manual.

TO AD JUST CHOKE CON TROL

The choke control has been preset at the factory and ad-

just ment should not be necessary. If adjustment is neces-

sary, see engne manual.

TO ADJUST CARBURETOR

Your carburetor is not adjustable. If your engine does not

operate properly due to suspected carburetor problems,

take your tractor to an authorized service center for repair

and/or adjustment.

TO REPLACE FUSE

Replace with 20 amp automotive-type plug-in fuse. The

fuse holder is located behind the dash.

Содержание 413420

Страница 44: ...44 SERVICE NOTES ...

Страница 45: ...45 SERVICE NOTES ...

Страница 46: ...46 SERVICE NOTES ...