Page 16

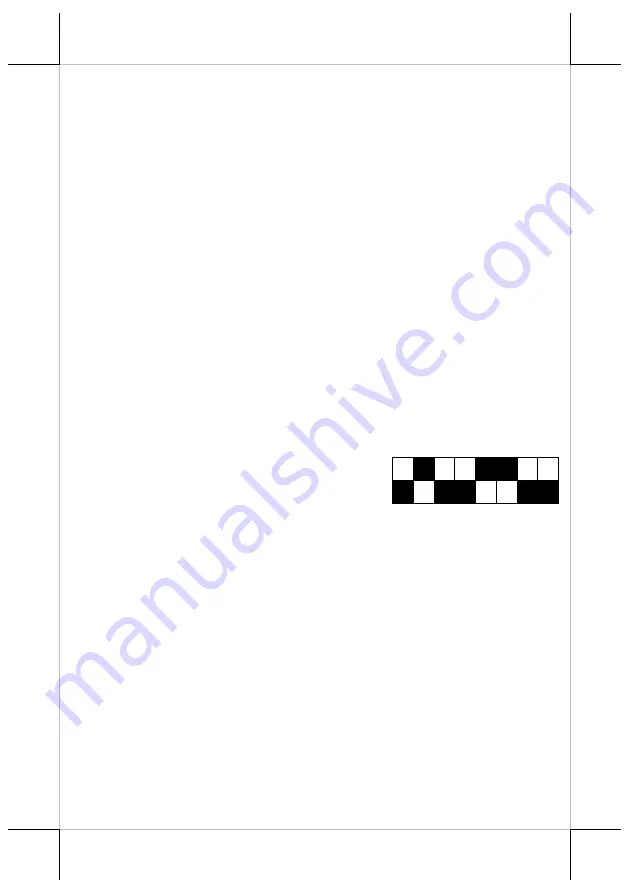

ON DIP

1

2

3

4

5

6

7

8

the paper may become discolored.

If thermal paper touches diazzo copy paper immediately after copying, the

printed surface may be discolored.

Use only water paste, starch paste, polyvinyl paste or CMC paste when

gluing thermal paper.

If thermal paper touches anything containing phthalic acid ester plasticizer

for a long time, the image formation ability may be reduced or the printed

image may fade.

Use of volatile organic solvents such as alcohol, ester and ketone or some

adhesive tapes on thermal paper can cause discoloration.

Thermal paper must not be stored with the printed surfaces against each

other as the prints may be transferred between the surfaces.

Since the paper roll is highly thermal sensitive, please keep it in a dark

place that is between 20% and 65% RH when not installed in the printer.

Avoid extended exposure to direct light. Use only products made from

polyethylene, polypropylene or polyester for storage of the thermal paper.

FURTHER TECHNICAL INFORMATION

PRINTER SETUP

There are two different ways to set up PP-6907.

The first way of setup is implemented through

the hardware DIP Switch on the bottom of printer

for setting up functions such as baud rate, paper

width and others. The second one is implemented

through a software utility to adjust the switch, such as printer density and other

functions.

These switch settings are described below.

Setup

through

Hardware DIP

Switch

On the bottom cover of the PP-6907 series thermal printer, there is a

screwed metal plate for setup window. In this window, there is an 8-

position DIP switch for printer setup. Please use a proper tool to change

the switch setting, if necessary. The functions of each position may evolve

with the revisions of the firmware. The information below applies to the

latest version to the date of print of this manual.