B.

SETUP WINDOW

On bottom cover of the Aura series thermal printer, there is

screwed a metal plate for setup window. In this window, there is a

8 position DIP switch for printer setup. Please use proper tool to

change the switch setting when necessary. The switch position

counting starts from the nearest edge of printer. The ON direction

points to the connector area of the printer. The OFF direction

points to the power switch. The functions of each position may

evolve with the revisions of the firmware. The information below

applies to the latest version to the date of print of this manual.

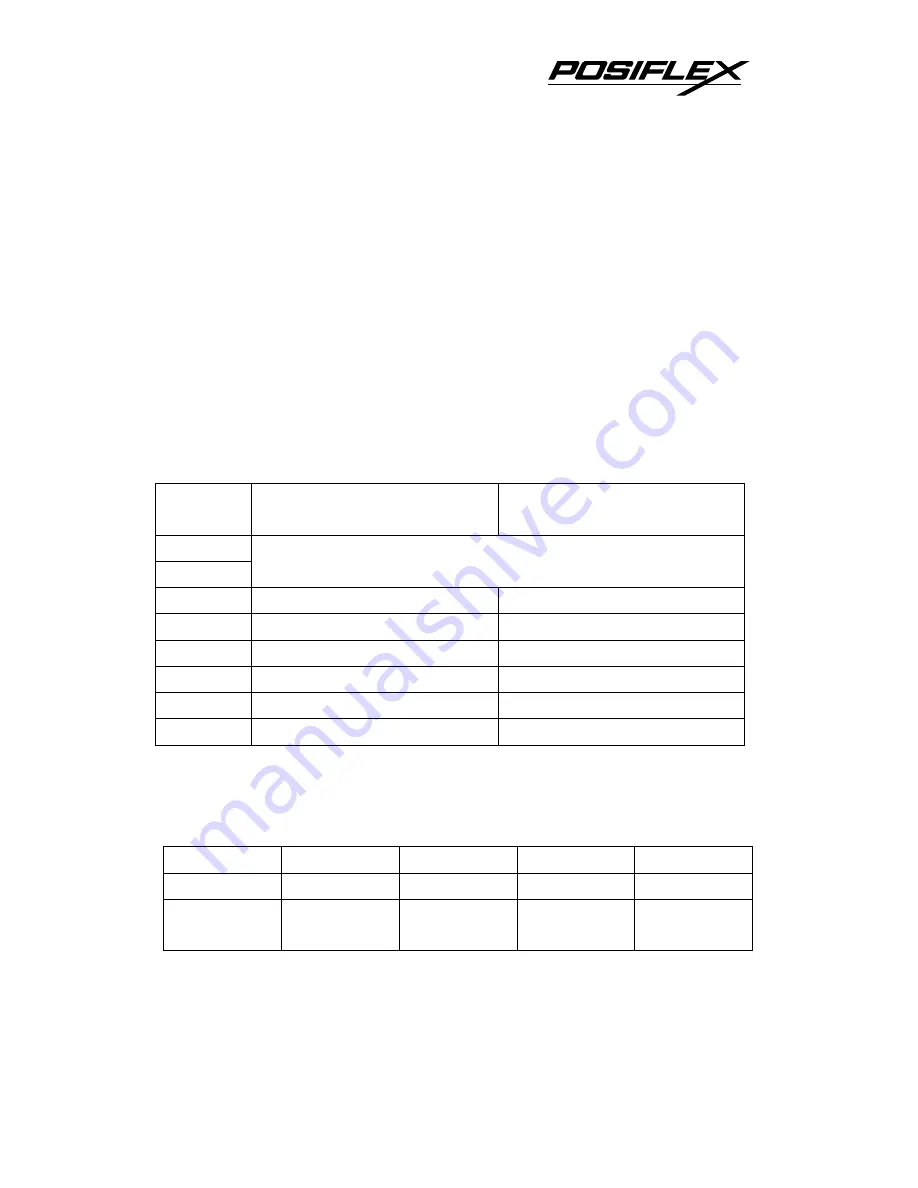

This 8 position DIP switch works as following:

Switch

position

ON OFF

1

2

RS232 baud rate definition or Parallel interface

definition (ref. separate table below)

3

Even parity

None parity

4

XON handshaking

Hardware handshaking

5

Busy on “buffer full”

Busy on “off line”

6

Immediate cut

Protective cut

7

CR code effective

CR code ineffective

8

Factory internal setting

Application standard mode

Effect of positions 1 & 2 on baud rate is defined as in table

below with parity check set according to position 3, number of

data bits always set to 8, and stop bit set to 1. When the parallel

interface is used, please set both positions to ON.

SW Pos. 1

ON OFF ON OFF

SW Pos. 2

ON ON OFF OFF

Baud rate

or Interface

38400 bps /

(Parallel)

4800 bps

9600 bps

19200 bps

Switch position 3 defines the parity check regulation in

serial interface. In Aura, it is selectable between even and none.

5 - 2