28

29

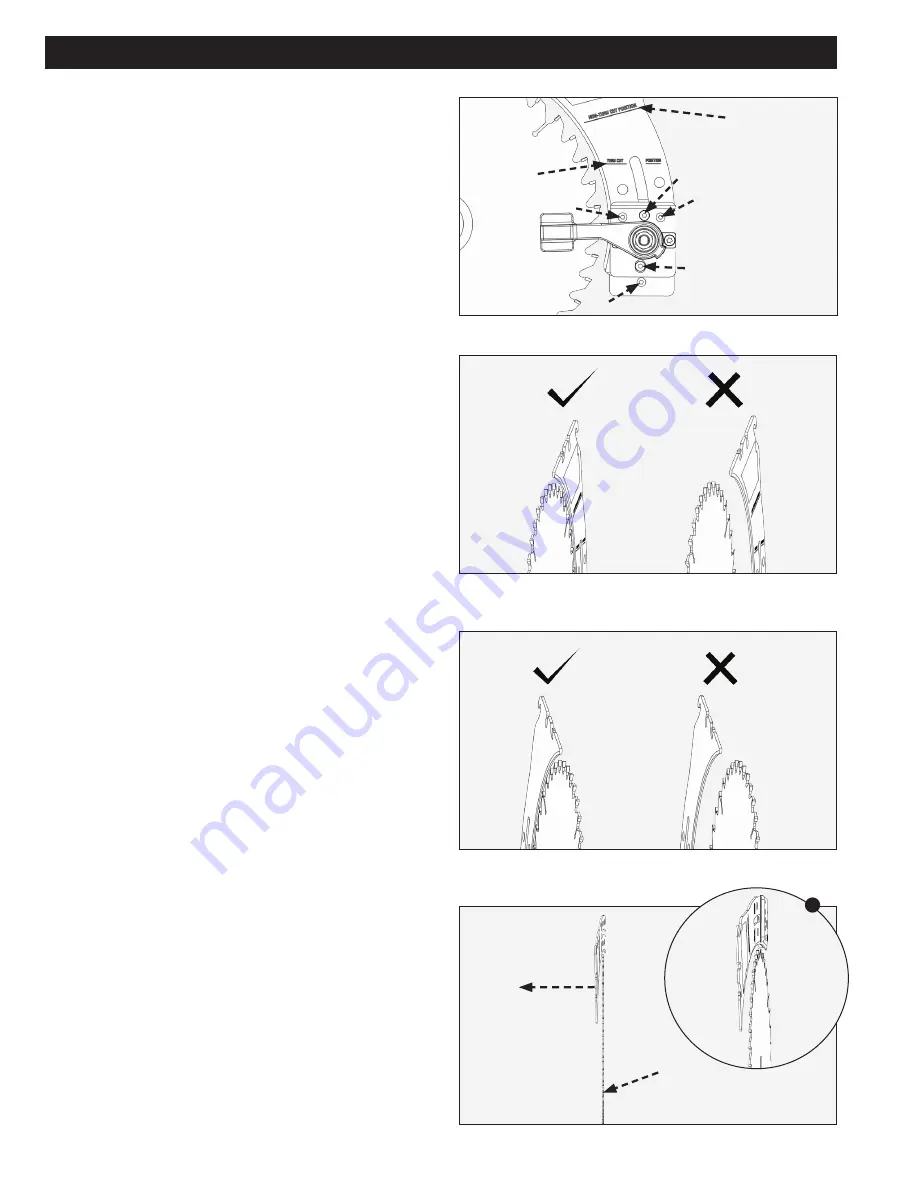

Your riving knife may be out of alignment if your work

piece is hitting the riving knife after the cut or causing

some binding during the cut. When this condition

occurs you will need to make an adjustment to the

riving knife alignment. The following procedures in this

section will assist you with making adjustments to the

riving knife alignment.

Locating point for THRU CUT POSITION as shown in

Fig. 37 (Customer should adjust the riving knife in this

position when making “THRU” cuts.)

NOTE:

You must locate the riving knife in this position

prior to making any alignment adjustments to the riving

knife alignment of the blade.

If a parallel adjustment is required, use Fig. 37 and Fig.

38 to make the following adjustments:

1. Loosen the 2 hex socket head screws (AA)

2. Tighten or loosen the adjustment screw (BB1) to

adjust the datum line if the riving knife to be aligned

to the blade.

3. Adjust set screw (BB2) and (BB3), to assist with

alignment of the riving knife to be parallel to the

blade.

4. Tighten hex socket head screws (AA).

If the riving knife has vertical misalignment, adjust as

follows using Fig. 37 and Fig. 39:

1. Loosen the 2 hex socket head screws (AA)

2. Make adjustments to (BB2) and (BB3), to align

riving knife to the blade. No adjustment is needed

for (BB1).

3. Tighten screws (AA).

If the riving knife has horizontal misalignment, adjust as

follows using Fig. 37 and Fig. 40:

1. Loosen the 2 hex socket head screws (AA).

2. Adjust screw (BB2) to align the riving knife to the

blade, if still out of alignment then adjust (BB3) until

proper alignment is acheived. Do not adjust (BB1).

3. Tighten screws (AA).

RIVING KNIFE ALIGNMENT

FIG. 37

AA

CORRECT

POSITION

CORRECT

POSITION

PARALLEL

SHIFT

DEFLECTIVE

RIVING KNIFE

AA

BB1

BB2

BB3

NON-THRU CUT

POSITION

THRU-CUT

POSITION

FIG. 38

FIG. 39

FIG. 40

BLADE

DIRECTION OF

MISALIGNMENT

MISALIGNMENT

OF RIVING KNIFE

a

Содержание PCX362010

Страница 31: ...31 NOTES ...