Page 8

EMHART TEKNOLOGIES

• 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 •

www.emhart.com

Note:

Numbers in

bold type

refer to call out numbers in illustration.

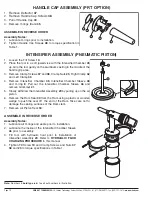

SERVICING THE JAWS, JAW PUSHER AND JAW PUSHER SPRING

Regularly cleaning the Jaws and front end parts will prevent mandrels sticking in the Jaws and extend the life

of the Jaws.

1. Disassemble the tool front end as described above. Clean Jaws

3

using a brush and solvent. If jaw teeth

show significant wear replace both jaws.

2. Check Jaw Pusher Spring

5

for fatigue. A new spring measures 2-1/8" (54mm) in length. Replace spring if

shorter than 1-7/8" (46mm).

3. Thoroughly clean the inside of the Jaw Guide

11

, Nose Housing

44

, the Jaw Pusher

22

and wipe out or blow

out debris from around other exposed parts.

4. Lightly oil Jaws

3

and Jaw pusher

22

before reassembling.

5. Reassemble parts in reverse order tightening Jaw Guide

11

, Nose Housing

44

and Nosepiece

12

to torque

specifications in Table 1.

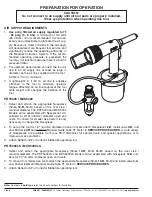

REPLENISHMENT OF HYDRAULIC FLUID

A shortened stroke indicates minor hydraulic fluid loss. Small amounts of fluid can be replaced without

disassembling the tool.

Equipment Needed:

Oil Replacement Screw, 3/8" - 24 Socket Head Cap Screw

Large slotted screwdriver

Hydraulic Fluid

Soft jawed vise

7/16" (11mm) open end wrench

Procedure

1. Place the tool in a soft-jaw vise, making sure the Fill Screw

10

is point-

ing up.

2. Remove the Nosepiece

12

, the Fill Screw

10

and Seal Washer

4

.

3. Screw the Oil Replacement Screw into the Nose Housing where the

Nosepiece

12

was removed. Tighten only until resistance is felt.

4. To properly add fluid, the Hydraulic Piston

26

must be pushed back. To

do this,

simultaneously turn the Oil Replacement Screw into the Nose

Housing (approximately 8-10 turns of the screw) while adding the oil

one drop at a time through the Fill Screw opening. Do not tighten the

Oil Replacement Screw since internal tool damage may result.

5. Allow bubbles to rise out of the oil and top off if necessary.

6. Reinstall Fill Screw

10

and Seal Washer

4

. Tighten securely. For torque

specifications see Table 1.

7. Remove the Oil Replacement Screw. Replace the Nosepiece

12

and

tighten securely.

8. Reconnect the air supply.

9. Loosen Fill Screw

10

very slightly, allowing excess oil to be forced out.

10. Wipe tool clean and tighten Fill Screw

10

to torque specifications in Table 1.

If oil loss is rapid or excessive, refer to the service manual for seal replacement procedures.

Caution:

The tool must be disconnected from the air supply before attempting

to replenish hydraulic fluid.

Caution:

Do not depress the trigger when Fill Screw 10 is loose. This will

cause oil to be forced out under great pressure.

MADE IN

U.S

.A.