12

GOLD 1-3 SK-GB-708

Right to make modifications without prior notice

Closed Opened

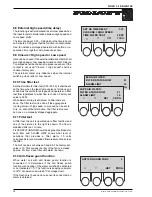

7.6. Throttle damper

Before the throttle damper is adjusted, duct calibration

shall be carried out, see 8.6.

The damper shall be fullyopened, pushed so that no part

is in the the exhaust air inlet (see sketch).

Set the supply and exhaust air flows on the display

(according to 7.5 above).

After that, make an adjustment which distributes the

total supply and exhaust air flow so that each diffusor

obtains the correct flow.

There after it is time to adjust the pressure balance in the

unit with the help of the damper so that the purging flow

goes to the exhaust air side.

On the external electrical enclosure there are two red

pressure nipples for measuring the negative pressure on

the supply and exhaust air side. At the nipples there are

a

+

for the pressure on the supply air side and a

-

for the

pressure on the exhaust air side.

Connect the manometer or other pressure meter to the

connections for

+

and

-

and measure both pressures.

NOTE! With both nipples negative pressures are

measured.

If the negative pressure on the exhaust air side is at least

as high as on supply air, the adjustment is ready.

If not, remove the inspection door, adjust the damper

slightly, put back the inspection door and measure the

pressures. Repeat until the negative pressure on the

exhaust air side is at least as high as on supply air side (0–

20 Pa).

New duct calibration should be done when the damper

has been adjusted.

WARNING!

Inspection hatches located on the pressure side behind

the fan must not be opened when the fan is operating.

The hatch can open suddenly and cause personal

injury.

Min flow l/s

Max flow l/s

Size

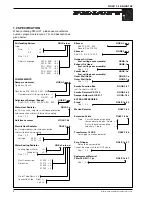

7.5. Flows

Where the flows are programmed in l/s and the smallest

step is10 l/s.

Min and max flows:

GOLD 1

70

320

2

110

500

3

230

900

Low speed flow can also be set to 0, which stops the unit

at times for low speed on the switching clock.

Programmed flows is automatically kept in GOLD.

:

: :

:

HIGH SPEED

::

LOW SPEED

700 l/s

SA

400 l/s

700 l/s

EA

400 l/s

RET

PROG