0000300349/230420/0 MDB-Diluter PRO

4

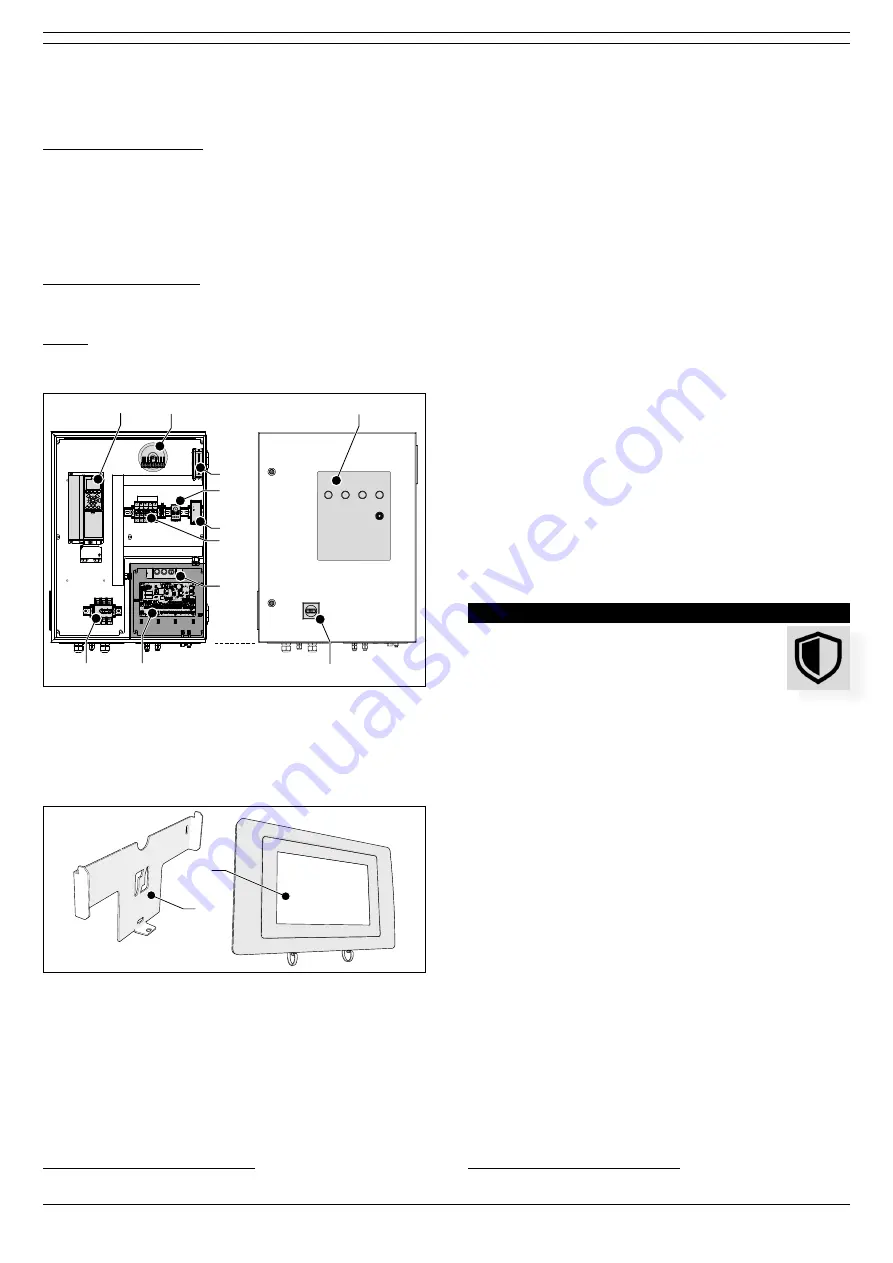

2.1.2 Control equipment

Panel

High voltage compartment

A VFD (frequency inverter)

B Transformer

C Cooling fan

D Thermostat

E Switch mode power supply

F Circuit protectors

3

G Main switch (interior parts)

Low voltage compartment

H PC board

I Manual controls

Outside

J Status panel

K Main switch (exterior parts)

Fig. 2.1

A

B

G

I

F

D

C

H

J

K

E

Main components Panel

HMI

A Touch screen

B Mounting bracket

Fig. 2.2

A

B

Main components HMI

Connection cables

- Panel

HMI cable

- motor cable

- PTC cable

- control cable (connected to the compressed air switch)

3. CE (400V): circuit breakers | UL (480/600V): fuses

2.2

Operation

2.2.1 MDB-Diluter

The air -that contains welding fume- is extracted through the

air inlet module on top of the unit. The larger particles and any

sparks are separated by a labyrinth-shaped

4

spark arrester.

Subsequently the air is cleaned by the eight filter cartridges.

The air then passes the extraction fan and a duct silencer. The

clean air is blown back into the workshop by the outlet unit

with adjustable nozzles.

The filter cartridges are cleaned individually from the inside

out by compressed air pulses. This filter cleaning system is

called the RamAir™ pulse amplifier. The dust and dirt particles

are collected in the dustbin.

The fan speed is pressure controlled.

Apart from air cleaning, the system optimises the present

natural ventilation (draught) and/or forced ventilation (roof/

wall fans) system and equally distributes the present welding

fume to reduce the background concentration of welding fume

in the workshop.

2.2.2 ControlPro

ControlPro is an intelligent platform that controls the filter

system as well as the connected extraction fan. It contains an

extensive feature package to monitor and arrange the

RamAir™ pulse amplifier (filter cleaning system), the required

airflow and the corresponding fan speed. By means of the

user-friendly HMI you can program all desired parameters. The

HMI gives a clear insight into the system status and

performance at all times.

ControlPro allows for remote access via a network connection.

3

SAFETY INSTRUCTIONS

General

The manufacturer does not accept any liability for

damage to the product or personal injury caused by

ignoring of the safety instructions in this manual, or

by negligence during installation, use, maintenance, and repair

of the product mentioned on the cover of this document and

any corresponding accessories. Specific working conditions or

used accessories may require additional safety instructions.

Immediately contact your supplier if you detect a potential

danger when using the product.

The user of the product is always fully responsible for

observing the local safety instructions and regulations.

Obey all applicable safety instructions and regulations.

User manual

- Everyone working on or with the product, must be familiar

with the contents of this manual and must strictly obey the

instructions therein. The management should instruct the

personnel in accordance with the manual and obey all

instructions and directions given.

- Do not change the order of the steps to perform.

- Always keep the manual with the product.

Pictograms and instructions on the product (if

present)

- The pictograms, warning and instructions attached to the

product are part of the safety features. They must not be

covered or removed and must be present and legible during

the entire life of the product.

- Immediately replace or repair damaged or illegible

pictograms, warnings and instructions.

4.

Refer to Fig. VI on page 28 for the airflow through the air inlet module