Service &

Maintenance

LOLER / SERVICE Repair Check List

Lift no:

Vehicle Rag:

Engineer’s Name:

Date:

Customer Details:

Address, Contact:

Tel. Number:

Poor

Ok

Good

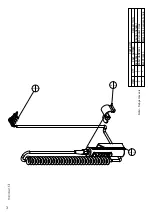

1 Roll Off Ramp (Ramp Stop) operation/ condition/ correctly fitted.

2 Roll Off Ramp wheels, operation/ condition/ correctly fitted.

3 Roll Off Ramp wheel rubbers

“O rings”

, operation/ condition/ correctly fitted.

4 Roll Off twin springs, (2 per side) operation/ condition/ correctly fitted.

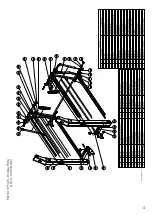

5 Bridge plate Aluminium, operation/ condition/ correctly fitted.

6 Bridge plate activation wheels/ linkages, operation/ condition/ correctly fitted.

7 Bridge plate torsion spring, operation/ condition/ correctly fitted.

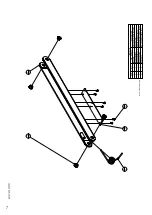

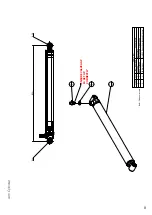

8 Platform- correct stowing position MUST be

“Past”

vertical.

9 Platform- correct horizontal position MUST be at 92° to vehicle floor.

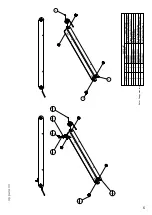

10 Platform Stow bearings, operation/ condition/ correctly fitted.

11 Platform operation should be smooth and controlled there should be NO erratic/

rough movement when raised or lowered.

12 Platform Gates, operation/ condition/ set and correctly fitted.

13 Platform Knuckles, operation/ condition/ correctly fitted. (Paint mark should be

centrally located between knuckle ends)

14 Platform Gate hinges, operation/ condition/ correctly fitted and lubricated.

15 Gas Struts, operation/ condition/ correctly fitted.

16 Vertical Stow bolts, operation/ condition/ set and correctly fitted.

17 All lift arm/ cylinder pins should be flush fitting and correctly fitted with blue glue.

18 All fasteners present and tight.

19 Arm Nipples correctly greased.

20 All hoses and protective sleeving, condition/ correctly fitted.

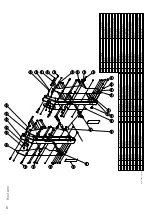

21 Hydraulic fittings in good condition/ securely tightened to 35Nm and confirmed

with paint pen.

22 Lifting cylinders, operation/ condition/ correctly fitted.(eg No signs of corrosion,

leaks, or loose caps)

23 Cleating and wear strips, condition/ correctly fitted.

24 Up/Down hydraulic pump operation/condition (relief valve)

25 Hand pump operation/condition/ check tightness

26 SWL Plate correctly fitted and displayed on Base Frame

27 Base Frame assembly, condition/ correctly fitted.

28 Lift Number correctly stamped on S/S plates.

Service &

Maintenance

10.8 Check List Access™ EA & Access™ EAB

10

10.8 Check List Access™ EA & Access™ EAB

When disposing of the machine, please comply with the

procedures imposed by the laws in force.

Generally the machine should be disassembled and identical materials grouped

together these must then be disposed of in accordance with local environmental

legislation.

Contact the local Authority to ensure that specific materials such as lubricants,

electrical/ electronic components are disposed of correctly.

YOU MUST RETURN THE MACHINE ID PLATES AND ANY

OTHER CONNECTED DOCUMENTS TO PLS WHEN THE

PRODUCT HAS BEEN RECYCLED.

Safe Disposal

11.1 Disposal Instructions Access™ EA & Access™ EAB

11

10

Содержание Access EA Series

Страница 7: ...1 General 1 5 Heath Safety Scooters Access EA Access EAB ...

Страница 33: ...Service Maintenance 10 10 2 Loler Access EA Access EAB ...

Страница 45: ...Diagrams M 13 2 Hydraulic Diagram Access EA Access EAB 13 ...

Страница 66: ...Notes Notes 15 15 ...