18

© 2006 Pioneer Supply International

18

© 2006 Pioneer Supply International

Adjusting V-Belt Tension

This must be done after approximately 16 hours of operation. During this first 16 hours the V-belts will stretch

and seat into the pulley grooves. After this 16 hours, the V-belts must be tensioned or V-belt life will be

severely reduced.

NOTE:

Pulleys and belts run warm. This is a normal condition. Allow them to cool before making adjust-

ments. Some black dust at the bottom of the belt housing is normal during the life of the V-belt.

The correct tension for the V-belts is 1/4" deflection when pushing the center with moderate pressure. Adjust/

replace belts by using the motor mount bolts (Figure 19-B) to control the tension. NOTE: Always change belts

as a matched set when replacing. If only one or two is replaced, the belt tension may not be even, causing

premature belt failure and possible injury.

Adjusting Alignment on Pulley

Using a straightedge, check to see if the motor pulley is in line with the shaft pulley (Figure 18). If they are not

in line, loosen screws as shown in figure 19-A. Move motor to left and right until adjusted to proper position

and then tighten screw again.

Motor Pulley

Shaft Pulley

Figure 18

Anti-Kickback Fingers

NOTE:

Proper operation of the anti-kickback fingers is

essential for the safe operation of this machine and to

prevent serious operator injury.

The anti-kickback fingers hang from a rod suspended

across the cutter head casting and should be inspected

regularly. Check the fingers (Figure 21) to ensure that

they swing freely and easily. If the fingers do not swing

freely and easily, blow or brush out the saw dust, and

clean them with a wood resin solvent. Do not apply oil

or other lubricants, which would attract dust and dirt.

Figure 21

Figure 19

A

B

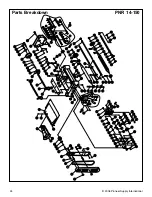

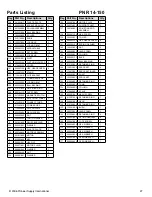

Содержание PNR 14-150

Страница 1: ... 2006 Pioneer Supply International Inc PNR 14 150 OPERATION MANUAL 15 Single Surface Thickness Planer ...

Страница 4: ...4 2006 Pioneer Supply International 4 2006 Pioneer Supply International ...

Страница 5: ... 2006 Pioneer Supply International 5 ...

Страница 6: ...6 2006 Pioneer Supply International 6 2006 Pioneer Supply International ...

Страница 24: ...24 2006 Pioneer Supply International 24 2006 Pioneer Supply International Parts Breakdown PNR 14 150 ...

Страница 26: ...26 2006 Pioneer Supply International 26 2006 Pioneer Supply International Parts Breakdown PNR 14 150 ...

Страница 28: ...28 2006 Pioneer Supply International 28 2006 Pioneer Supply International ...

Страница 29: ... 2006 Pioneer Supply International 29 ...

Страница 30: ...30 2006 Pioneer Supply International 30 2006 Pioneer Supply International ...

Страница 31: ... 2006 Pioneer Supply International 31 ...