CAUTION

Risk of crushing by moving parts!

Risk of minor injuries from crushing between the moving parts of the V-417.xx6211E0 or the

load and a fixed part or obstacle.

►

Use safeguards to protect limbs in areas where they could be caught by moving parts.

►

Maintain the safety distances according to DIN EN ISO 13857 when installing protective

structures.

NOTICE

Damage due to collisions!

Collisions can damage the V-417.xx6211E0, the load to be moved, and the surroundings.

►

Make sure that collisions are not possible between the V-417.xx6211E0, the load to be

moved, and the surroundings in the motion range of the V-417.xx6211E0.

►

Do not place any cables or other objects in areas where they could be caught by moving

parts.

NOTICE

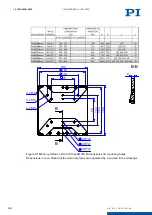

Excessively long screws and locating pins

Screws and locating pins that are inserted too deeply can damage the V-417.xx6211E0.

►

Pay attention to the

depth of the mounting and locating holes (p. 29)

V-417.xx6211E0.

►

Only use screws and locating pins of the correct length for the respective mounting holes.

Mounting the V-417.xx6211E0 onto an Underlying Surface

1. If necessary: Insert the locating pins into the corresponding holes in the underlying

surface.

2. Align the V-417.xx6211E0 on underlying surface so that the corresponding mounting holes

in the V-417.xx6211E0 and underlying surface in line.

3. Put the V-417.xx6211E0 onto the underlying surface so that the locating pins can be

inserted into the corresponding locating holes with the V-417.xx6211E0.

4. If necessary: Allow access to the mounting holes in the base body of the V-417.xx6211E0.

Possible measures:

■

Temporary

startup of the V-417.xx6211E0 (p. 19)

platform to a suitable position

■

Push the motion platform by hand (p. 21)

5. If necessary, use a flat washer with each screw and insert the screws through the washer

into the mounting hole.

6. Tighten the screws in all accessible mounting holes completely.

Recommended torque: 3 Nm

7. If necessary: Repeat steps 4 to 6 for all concealed mounting holes.

8. Check that the V-417.xx6211E0 is fixed firmly to the underlying surface.

6.2

Connecting the V-417.xx6211E0 to the Protective Earth Conductor

The V-417.xx6211E0 must be connected to the protective earth conductor via the drive

connector.

It is only necessary to connect the V-417.xx6211E0's base body to the protective earth

conductor when the following conditions are met:

■

The electronics do not guarantee safe connection of the drive connector to the ground

potential.

6 INSTALLATION

V417M0009EN

‒

4/26/2019

14

M O T I O N | P O S I T I O N I N G