Handling and Fitting Manual for semi-flexible solar panels EFLX series

Page 8 of 12

Even a small amount of trapped air can result in premature reduction in solar panel

output, or a complete failure of the solar panel, due to the constant warming and cooling

of the air each day and night, which increases surface tension and stretches the surface

material. This may also contribute to the development of dry solder joints between the

solar cells.

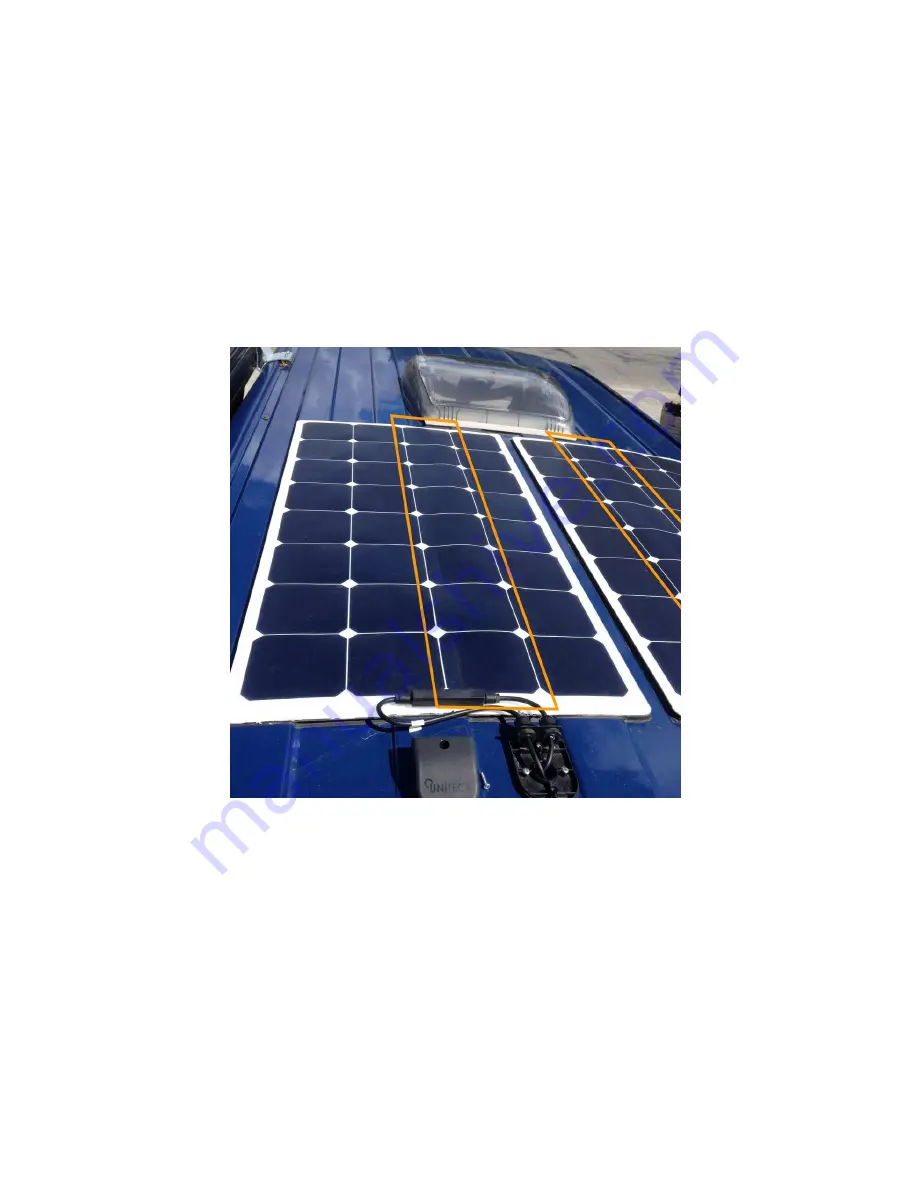

To illustrate the danger of trapped air underneath the solar panel, the following picture

shows an incorrect solar panel installation on a ridged van roof, where the spaces

between the ridges were not filled in prior to the installation. The edges of the solar

panels were mistakenly sealed; trapping air under the solar panel. In hot sunny weather,

the pressure of the hot air in gaps between the ridges increased so much that the solar

panels bulged, cracking the solar cells and causing permanent failure of the panels.

To avoid these problems, there are two main mounting options:

1) Cover the entire underside of the solar panel with a layer of adhesive, spreading

it evenly with a trowel or a similar tool.

2) Apply the adhesive to the underside of the solar panel in parallel beads and do

not seal the edges of the solar panel. This will make the solar panel breathable.

The second option is recommended, as it is also good for temperature expansion /

contraction of the mounting surface material itself (particularly common in metal roofs).

Apply thick 10-12mm adhesive beads on the rear of the solar panel, in parallel to each

other, as shown in the diagram below: