DDC Instructions

20

107E6 CRT

Go to cover page

General

DDC Data Re-programming

Analog DDC IC, & EEPROM

Additional information

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed"

".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA). Extended

Display Identification Data(EDID) information may be also obtained from

VESA.

1.

An i486 (or above) personal computer or compatible.

2.

Microsoft operation system Windows 95/98 .

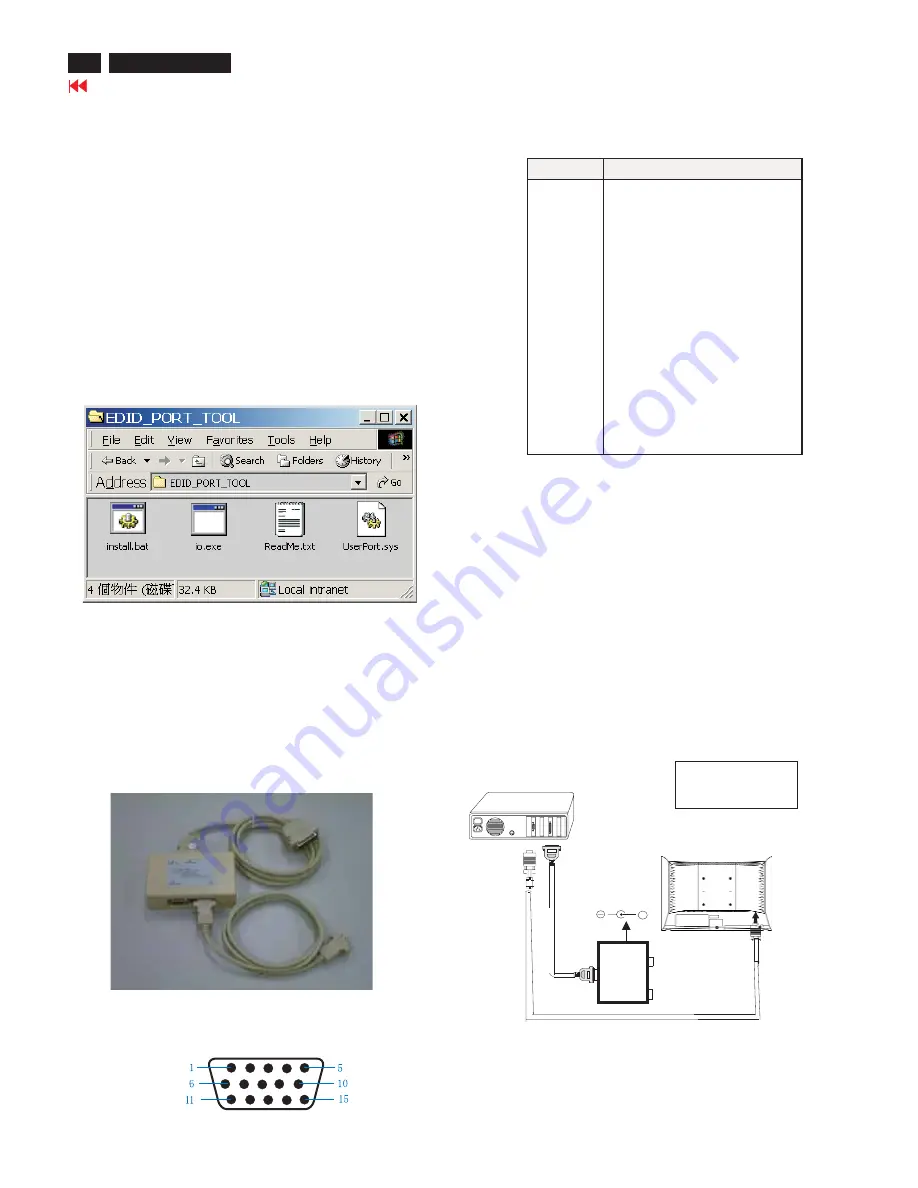

Y

o Install the EDID_PORT_Tool under Win2000/XP . As

Fig. 1 .

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

4.

A/D Alignment kits (12NC: 3138 106 10079) shown as Fig. 2:

inclusion :

a. Alignment box x1

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

Note: The EDID46.EXE is a windows-based program, which cannot be

run in MS-DOS.

System and equipment requirements

ou have t

3.

EDID301.EXE program .

Pin assignment

15 -pin D-Sub Connector

Configuration and procedure

There is no Hardware DDC (DDC IC) anymore. Main EEPROM stores

all factory settings and DDC data (EDID code) which is also called

Software DDC. The following section describes the connection and

procedure for Software DDC application. The main EEPROM can be re-

programmed by enabling '' factory memory data write'' function on the

DDC program (EDID301.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due

to sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID301.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8-12V DC power source to the Alignment box by

plugging a DC power cord .

Step 2: Connecting printer cable and D-Sub cable of monitor as Fig. 3

Fig. 3

Fig. 2

Fig. 1

Pin No.

IBM II standard

1

Red video input

2

G

reen video input

3

Blue video input

4

G

nd

5

For self-test (pc gnd)

6

Red video ground

7

G

reen video ground

8

Blue video ground

9

DDC5V from PC

10

G

nd

11

G

nd

12

Bidirectional Data (SDA)

13

H. SYNC

14

V. SYNC (VC

LK

)

15

Data clock (SC

L

)

Fig. 4

PC

1=Power connector

2=D-SUB connector

To

printer

port

(

L

TP1)

DC Power

8-12 V

Printer

Port

To

Monitor

To PC

1

2

----->

----->

TO VIDEO CARD

+

Содержание 107E61/00

Страница 5: ...Go to cover page 107E6 CRT 5 OSD Tree The OSD tree ...

Страница 35: ...35 107E6 CRT Go to cover page Wiring Diagram ...

Страница 38: ...Go to cover page 38 107E6 CRT Main Board C B A 1 ...

Страница 39: ...39 107E6 CRT Go to cover page Main Board C B A 2 ...

Страница 41: ...41 107E6 CRT Go to cover page Video Board C B A 1 ...

Страница 42: ...Video Board C B A 2 Go to cover page 42 107E6 CRT ...

Страница 43: ...43 107E6 CRT Go to cover page Control Schematic Diagram C B A ...