___________________________________________________________________________________________________________

PFT N2V/N2 FU 400V

18

Measures at the end of work and when cleaning, maintenance, transport

12/2004

___________________________________________________________________________________________________________

_______________________________________________________________________________________

Knauf PFT GmbH & Co.KG

Tel.

+49 (0) 9323/31-760

Postfach 60

Fax

+49 (0) 9323/31-770

D-97343 Iphofen

Internet

www.pft.de

_______________________________________________________________________________________

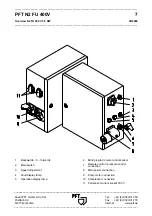

- Empty material hopper.

- Run pump motor briefly in reverse (to reduce pressure).

- The mortar pressure gauge must show 0 bar.

- Switch off the machine and pull out the power cable from the mains connection.

- Disconnect and clean the hoses.

- Dismantle the spraying gun and clean it.

- Clean air nozzles.

- Clean the hoses incl. the mortar pressure gauge using the water mains supply and

water soaked sponge balls.

- Completely empty the hoses.

NOTE:

The corresponding sponge balls must be used separately for different hose diameters.

-

Repeat this procedure several times if required.

NOTE:

Clean the machine with a sponge, brush and water.

Do not clean with a high pressure cleaner or steam cleaner as water can penetrate

into the bearings, switches, sockets, plugs etc. and damage the system.

-

Clean the material hopper.

-

Empty the dirty water via the cleaning opening.

-

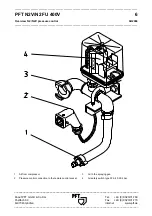

Rinse the pump with clean water.

-

Rinse out the pressure flange.

Maintenance

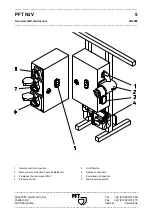

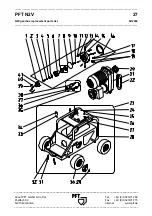

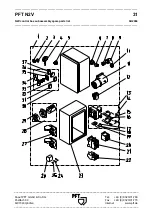

Oil sealing unit oil level check

The oil level must be checked every day on the inspection window of the oil sealing

unit (1/2 height).

If required, top up with motor oil 10 W 40.

Otherwise the

PFT N2V/N2 FU 400

conveying pump requires no maintenance.

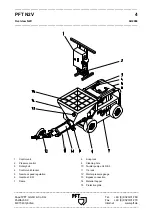

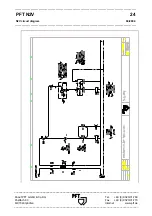

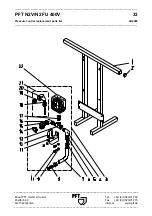

Transport

Only transport the

PFT N2V/N2 FU 400

secured to a Euro pallet.