PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Cleaning

24

2017-08-07

20 Cleaning

Locking to prevent reactivation

DANGER!

Danger to life from unauthorized reactivation!

While working at the machine one is exposed to

the danger that the power supply may be activated

without authorization. This exposes the persons in

the danger zone to the risk of death.

– Before starting work, switch off all power

supplies and lock them against reactivation.

NOTE:

The machine must be cleaned daily after work and

after long pauses.

Connect

1

/

2

" water hose with Geka coupling (Item no. 20 21 11 00)

and spray nozzle (Item no. 20 21 57 00) to water mains.

Cleaning should take place in the following 5 steps:

•

When the hopper is 1/3 full, reduce the water entry at the needle

valve by a quarter. Switch off the PFT HM 24 as soon as highly

diluted mortar is discharged.

•

Remove the coupling of the power cable before disconnecting

the mixing tube, or else the safety hook on the machine will block

the coupling.

•

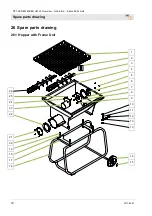

Open the snaps on the mixing tube and remove it. Release the

mixing shaft and clean it along with the mixing tube. Use a trowel

and water for this purpose.

•

Clean the hopper on the outside with a brush or dry mop. Use

water to clean the hopper only when it is empty.

NOTE:

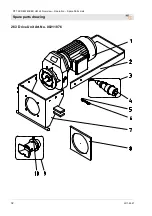

No water should enter the bearings or electrical

parts ( plug, main switch, motor connections box).

While assembling cleaned parts, make sure they are

really dry and clean. Connect mixing shaft to dosing

shaft.

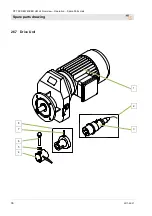

NOTE:

Keep all snaps and seals clean.

Grease bearing tang and connectors regularly.