9

Installation and Operating Instructions for Newbourne 40i Inset Inset Ecodesign Multi Fuel Stove

Ref: Pevex1030/AH/ver1: 1 April 2019

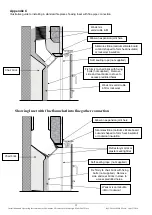

Once the lower vermiculite baffle has been removed then it is possible to remove the upper steel baffle and gain

access to the flue. Removal is achieved by un-doing the 2 allen key locking bolts by 1-2 turns and drawing it

forward to allow the bolt heads to pass through the slots. Reassemble is the reverse by hooking the front of the

baffle over the bolt heads and sliding it backwards and retighten the bolts.

CHIMNEY IMPORTANT WARNING

This stove must not be installed into a chimney that serves any other heating appliance. The chimney must be

a minimum height of 4.5 metres overall height and be in accordance with Building Regulations Approved

Document J and reference should be made to British Standard BS EN 15287-1:2007 design, installation and

commissioning of chimneys. Any chimney, either masonry or a prefabricated stainless steel system must be

constructed and installed according to building regulations. It is recommended that the minimum diameter of

the flue liner be 150mm although for a smoke approved appliance then a 125mm can be used. For new masonry

chimneys we recommend pumice cement liners.

A chimney draught of at least .06” (12Pa or 1.5mm) is

recommended. If it is found that there is excessive draught in the chimney then a draught stabiliser should be

fitted.

Provision must be made for easy sweeping of the chimney. A soot door can be built into a masonry chimney

and flue pipe is available with cleaning doors.

Any bend in the chimney or connecting fluepipe should not exceed 45º and 90º bends should not be

used.

THE CHIMNEY CONNECTION.

The flue pipe for connecting the appliance to the chimney must be installed according to Building Regulations

Approved Document J and its diameter must be not less than the diameter of the outlet of the appliance. The

fluepipe must be adequately sealed to both the stove and the chimney to avoid any leakage.

We recommend also that no more than 1metre of plain un-insulated flue pipe be used to connect to the chimney.

ALL CHIMNEYS SHOULD BE SWEPT AND INSPECTED BEFORE INSTALLATION OF ANY APPLIANCE

For relining existing chimneys 316 or 904 grade stainless steel liners or pumice cement liners in accordance with

Building Regulations Approved Document J should be used. Liners should be suitably insulated. We

recommended that any chimney relining is carried out by an experienced and competent installer who is HETAS

registered (see www.hetas.co.uk). The HETAS Guide to Approved Products and Services lists Chimneys and

lining systems suitable for use with solid fuel.

SWEEPING THROUGH NEWBOURNE 40I INSET.

It is possible to sweep through the Newbourne 40i Inset Ecodesign Stove. Remove the baffles as described

above, and access can be gained to the flue pipe.

VENTILATION

Purpose made ventilation is not required on the Newbourne 40i Inset Ecodesign stove for houses built before

2008. Houses built after 2008 where the air leakage rate is less than 5m3/hour/m

2

then a ventilator equivalent

to 550mm

2

per kW output will be required

(4kW x 550mm = 2200mm

2

).

COMMISSIONING

The installer should carry out the following checks and ensure that the stove is fully functional. We strongly

recommend that a first firing is included in the commissioning process

1. Check all flue pipe connections

2. Check door latch mechanism

3. Check door and glass seals are all intact and secure

4. Warm chimney and check draught.

5. Instruct customer in use of stove.

1. Two M8 allen key bolts holds

the upper steel baffle in place.

Undo by 1-2 turns

2. Allen key bolt

3. Steel baffle can be drawn

forward and it should drop down

and then you have access to the

flue