6

VB230/400-6/25/30LT

6.

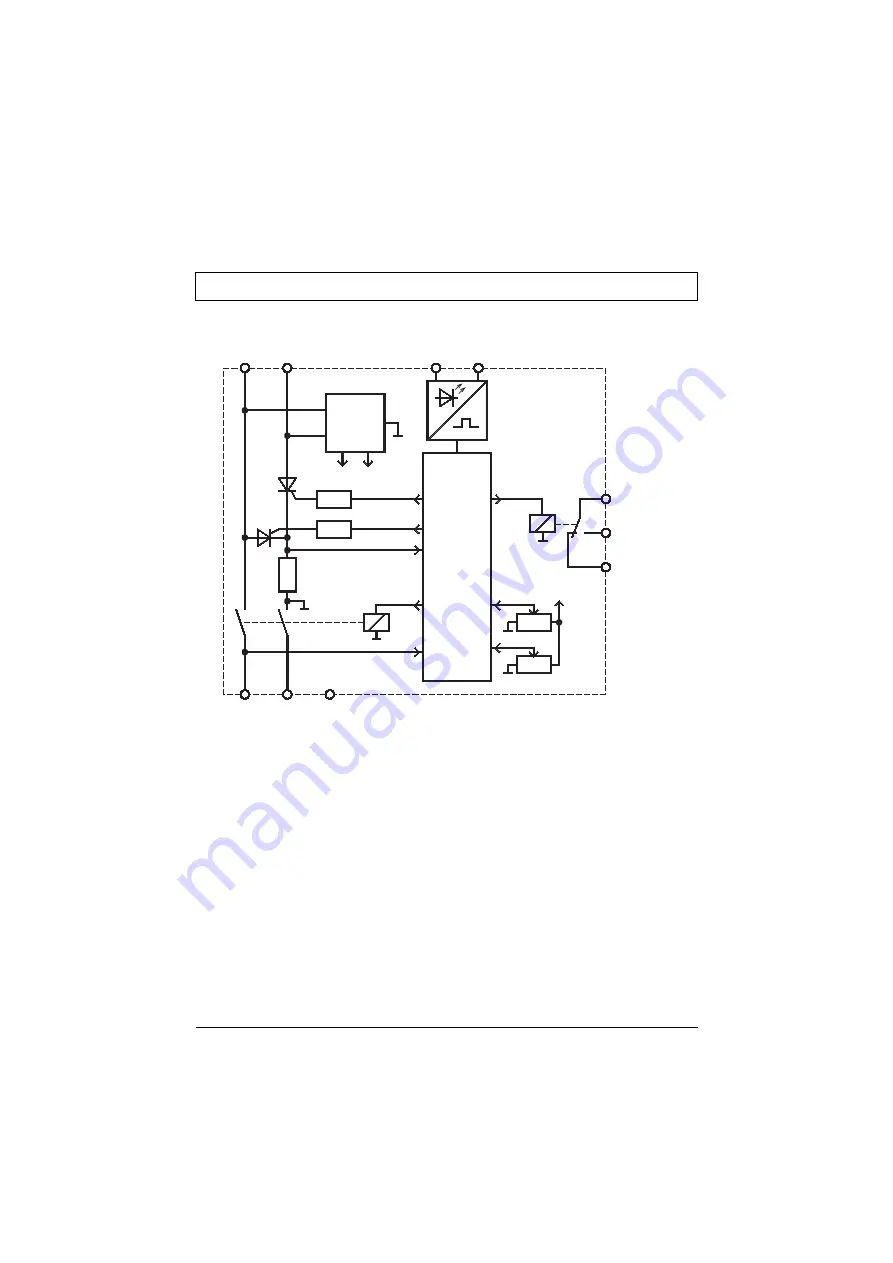

Block diagram

7.

Functional description (see connection diagram)

After the operating voltage on 1L1 and 3L2 has been switched on, the main contactor interlock

X5, X6, the fault signaling contact closes. The motor can be started.

A starting logic makes sure that, when switching the plant on with the master switch while the

motor is still switched off, braking is not initiated.

The fully automatic run of the braking interval starts when the normally closed contact (connected

to the terminals X3, X4) of the motor contactor is reclosed. During braking, the main contactor is

interlocked via the contact X5, X6. After a delay time which, dependent on the amount of the

remanent voltage of the motor, optimizes itself, the integrated braking relay pulls in. After the

contact bounce time has been waited out, a controlled d.c. current is fed into the motor winding.

The magnetic field resulting from this has a braking effect on the still rotating rotor. The d.c.

current is generated by a thyristor phase control. Special suppressor circuits protect the power

semiconductors against overvoltage. With the potentiometer „I“, the braking current (and thus the

braking torque) can be adjusted within a range of 10 … 100% of the rated device current.The

length of time the braking current is to flow can be adjusted with the potentiometer „t“ within a

range of 0...30s/60s. To protect the braking device against overloading in the case of braking

times exceeding 20s, the adjustable maximum braking current (rated device current) decreases.

Controller

1L1

3L2

2T1

4T2

6T3

X5

X6

X3

X4

X7

Interlocking

24V 5V

Power

supply

unit

Braking

time

Braking

current

+5V

Содержание VB 230-25LT

Страница 23: ...22 VB230 400 6 25 30LT...

Страница 24: ...VB230 400 6 25 30LT 23...

Страница 25: ...24 VB230 400 6 25 30LT...

Страница 26: ......