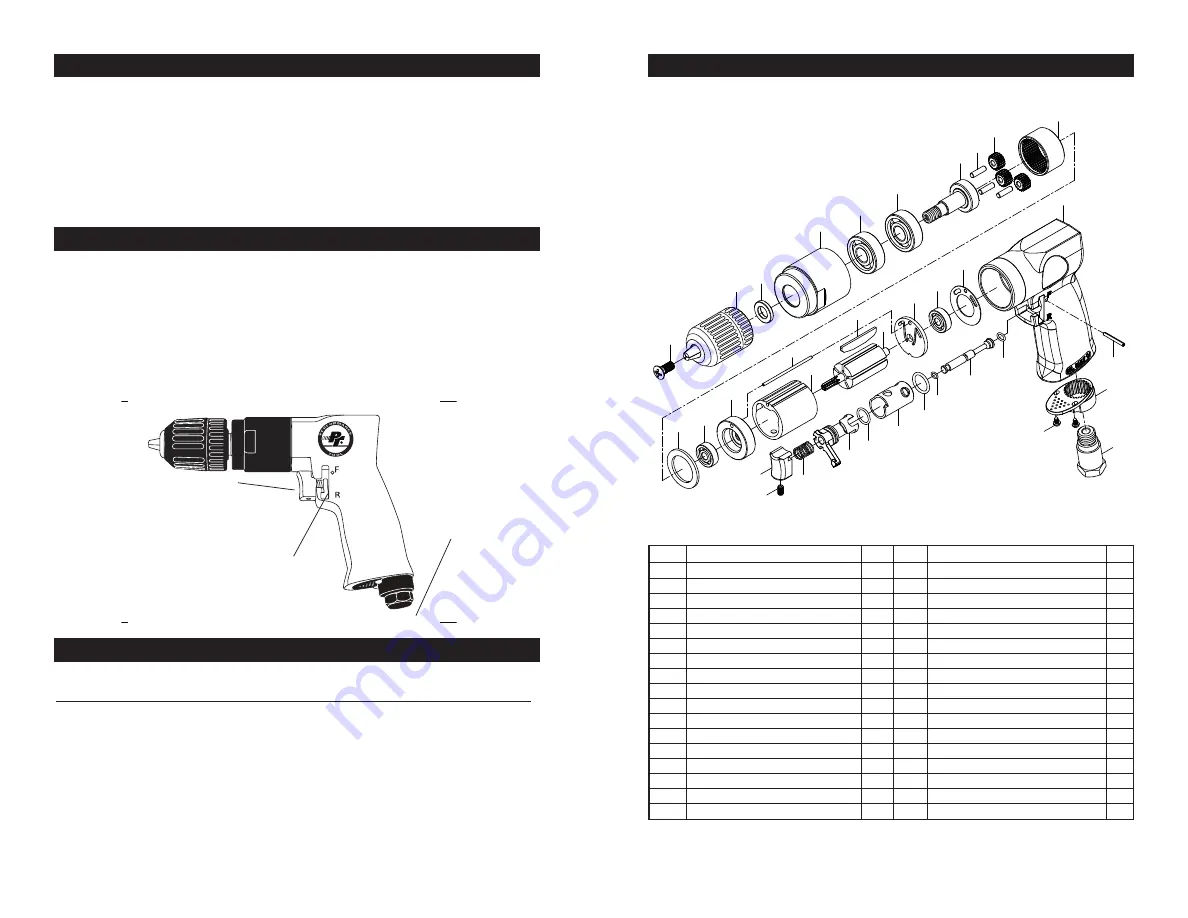

1

Housing

1

2

O-Ring

1

3

Switch Pin

1

4

O-Ring

1

5

O-Ring

1

6

Bushing

1

7

O-Ring

1

8

Direction Lever

1

9

Spring

1

10

Trigger

1

11

Trigger Nut

1

12

Trigger Pin

1

13

Exhaust Diffuser

1

14

Screw

2

15

Air Inlet

1

16

Seal Gasket

1

17

Rear Bearing

2

18

Rear Cover

1

19

Rotor

1

20

Rotor Blade

5

21

Cylinder

1

22

Fixed Pin

1

23

Front Cover

1

24

V-Gasket

1

25

Gear Ring

1

26

Gear

3

27

Gear Pin

3

28

Spindle

1

29

Bearing

2

30

Clamp Nut

1

31

Bushing

1

32

3/8 in. Chuck

1

33

Chuck Screw

1

PARTS LIST

33

32

31

30

29

29

28

27

26

25

33

24

17

23

22

20

21

19

18

17

16

10

11

9

8

7

6

4

3

5

2

12

13

15

14

INDEX DESCRIPTION

QTY INDEX DESCRIPTION

QTY

3

4

1. Use of a center punch to mark the starting point of a hole is recommended when drilling

metals with this tool. Place drill against work before starting motor. Do not apply too much

pressure to the drill as this can cause the bit to overheat and break. When the hole is drilled,

do not stop the drill until it is withdrawn from work.

2. If the drill should bind and stop inside the work, release the trigger immediately and

determine the cause. If removal of bit from the drill is necessary, disconnect the drill from the

air source before removing. Do not attempt to free the bit by forcing it with the drill.

3. A forward and reverse lever permits the tool to run in a forward (clockwise) rotation or in

reverse (Counter-clockwise) rotation. Do not attempt to change direction while tool is running.

OPERATION

Clean air of correct air pressure is recommended for the power supply for this tool. A maximum

of 90 PSI at the tool is recommended for most air tools of this class. Check specifications

section for recommended pressure. (Depending on length of air hose and other circumstances,

air pressure at compressor may need to be increased to 100 PSI to ensure 90 PSI at the tool.)

Water in the air hose and compressor tank contributes to reduced performance and damage of

the air tool. Drain the air tank and filters before each use and as necessary to keep the air

supply dry.

Hose length over 25’ causes loss in line pressure. Increase hose I.D. or increase compressor

pressure to compensate for the pressure loss. Use an in-line pressure regulator with gauge if air

inlet pressure is critical.

AIR SOURCE

Forward/Reverse Lever

Air Inlet

Trigger

INSUFFICIENT POWER:

Probable Cause

Solution

Dirty or clogged air passages......... Flush and lubricate tool, drain air tank and supply line

Insufficient air supply ...................... Increase line pressure, Make sure compressor

matches tool's air pressure and consumption needs

Air leakage ...................................... Use PTFE tape at all fittings and joints. Check tool for

worn or damaged O-rings & seals.

Worn/damaged wear & tear parts .. Replace as necessary.

Tool matching ................................. Be sure you are using a tool suited for the torque

requirements of the job at hand.

TROUBLESHOOTING