TTR-08A Electromechanical Tripod Turnstile

10 MAINTENANCE

The turnstile housing maintenance is required once a year or in case of some technical

failures. The maintenance should be carried out by qualified mechanic only.

Caution!

Prior to the turnstile maintenance works disconnect the turnstile power supply

from the AC mains.

The turnstile maintenance works should be carried out in the following order:

1. Switch off the turnstile power supply. The barrier arm will automatically fall down at

that.

2. Unscrew 3 M8 screws to remove the hub with the barrier arms.

3. Check security of mounting of the barrier arms (3) to the hub and if needed, tighten

the barrier arms fixing screws (3).

4. Lubricate the friction units of the barrier arm drop mechanism (automatic folding of

barrier arm “anti-panic”) and barrier arms hinged connections to the hub with

Energrease L21 M

or similar lubricant.

5. Remove the cover (2) with LED indication block from the turnstile housing. The

order is given in Chapter 6.

6. Remove the reinforcement plate (Fig. 11). In order to do this, loosen 4 screws,

which are fixing the plate.

7. Check visually the resetting device (pusher, springs and roller), the arm rotation

sensors and the damper (Fig. 14).

Caution!

Avoid the ingress of lubricant on the arm rotation sensor disc and the roller

surfaces.

8. Remove dust from the arm rotation sensor disc, located in the spacing of the arm

rotation optical sensors, with alcohol-gasoline blend applied with a cloth. Avoid the

ingress of dust on the operational spacing of the both arm rotation optical sensors.

9. Lubricate friction joints of the turnstile mechanism in the following points:

a. with

Chain and Rope Lube Spray - WEICON

lubricate the rotation axis of the

stoppers (1,2), roller (3) and the pusher arm (5, Fig. 14);

b. with

Energrease L21 M

or similar lubricant treat the resetting mechanism springs

fixing points (4, 6);

c. with

Chain and Rope Lube Spray - WEICON

lubricate passageway emergency

unlocking mechanism details.

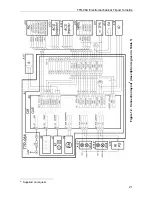

10. Check the reliability of the cable connections to the CLB connector blocks and

XS1

out connector block and if necessary tighten the cable fixing screws.

11. Install the reinforcement cover in reverse order

12. Connect the

S1

cable connector of the indication board to the CLB and mount the

cover with LED display (2) back into its place in the reverse order to the

dismantling. When the cover mounting is carried out correctly it does not need

much effort.

13. Install the hub (5) with barrier arms (3) as indicated in section 8.4

27

Содержание TTR-08A

Страница 34: ...www perco com...