Pump Storage

Drain pump to prevent freezing.

Keep motor dry and loosely covered. Do not wrap with

plastic sheeting; trapped moisture could cause corrosion

or insulation deterioration.

NOTICE: A good rust inhibitor in the liquid end of

cast iron pumps is recommended to prevent excessive

corrosion.

Pump Start-Up After Storage

Replace all drain plugs and close all drain valves in

the system.

Be sure all connections are tightly sealed.

After initial check is made, fill pump according to

Priming the Pump.

Shaft Seal Replacement

NOTICE: The highly polished and lapped faces of the

seal are easily damaged. Follow instructions and handle

the seal with care.

Hazardous voltage. Be sure unit is grounded

and power disconnected before attempting any work on

pump or motor.

Removal Of Old Seal

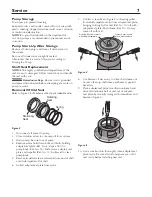

Refer to Figure 3 for Mechanical Seal parts indentification.

1. Disconnect all power to pump.

2. Close isolation valves to cut pump off from system.

3. Drain pump; be sure to vent pump.

4. Remove motor hold down bolts and bolts holding

adapter/seal plate (Ref. No. 6, Repair Parts) to

pump body (Ref. No. 20). Slide motor, adapter/ seal

plate and impeller (Ref. No. 12) backward to clear

pump body.

5. Remove impeller screw and washer from end of shaft

and slide impeller off of shaft.

6. Unbolt adapter/seal plate from motor.

7. Use two screwdrivers (Figure 4) or bearing puller

to carefully separate motor from adapter/seal plate,

bringing rotating half of seal (Ref. No. 10) off with

adapter/seal plate. Shaft sleeve (Ref. No. 2A) may

come off with seal.

8. Use hammer, if necessary, to drive shaft sleeve out

of seal. Clean up shaft sleeve with emery paper if

necessary.

9. Place adapter/seal plate face down on bench and

drive old stationary half of seal out of adapter/

seal plate by carefully taping with screwdriver and

hammer (Figure 5).

10. Use a wire brush to thoroughly clean adapter/seal

plate cavity. Be sure all dust and grime are out of

seal cavity before installing new seal.

Stationary

Seat

Rotating

Seal

Spring

1419 1294

Figure 3

1421 1294

Figure 5

If Gear Puller is used,

place jackscrew here.

Rotating Seat will come off

with adapter/sealplate.

1420 1294

Figure 4

Service 7

Содержание S40093

Страница 11: ...This page intentionally left blank...

Страница 12: ......